Как да отпечатате PPS-CF нишка перфектно ?

Table of Contents

- 1.Как за сушене на Ultra PPS-CF?

- 2.Препоръчителни параметри за печат и аксесоари за печат на PPS-CF

- 3.Как за извършване на отгряване на PPS-CF печатни части?

-

4. Какви са предимствата на QIDI PPS-CF?

- a. Свръхвисока устойчивост на топлина и пламъци, осигурява надеждна гаранция за използване в ключови области

- b. Отлична устойчивост на разтворители и химикали, идеална за използване в химическата промишленост

- в. Свръхниско водопоглъщане, най-добрият избор за взискателни изисквания за устойчивост на влага

- г. Отлични механични свойства, отговарящи на изискванията за висока точност

QIDI PPS-CF е подсилен с въглеродни влакна полифенилен сулфид (PPS) композитен материал. Комбинацията от PPS и въглеродни влакна придава на PPS-CF отлични свойства, включително изключителна устойчивост на разтворители, устойчивост на корозия, устойчивост на топлина, забавяне на горенето, ултра-ниска абсорбция на влага и изключителни механични характеристики. Тази статия ще предостави изчерпателен преглед на операциите за изсушаване преди печат, препоръчителните настройки за печат и обработките за отгряване, за да ви помогне да постигнете с лекота резултати от печат, близки до индустриален клас.

1.Как за сушене на Ultra PPS-CF?

Характеристиката на нишката, абсорбираща вода след отваряне, се препоръчва да се изсуши преди печат с този PPS-CF нишка.

Операция на сушене:

- Уверете се, че повърхността на PPS-CF нишката е достатъчно чиста и без чужди предмети.

- Поставете PPS-CF нишка в сушилня.

- Задайте температурата на сушилнята на 120 ° C и времето за сушене на 8 часа. Конкретното време се определя според нивото на влажност на нишката.

- Започнете да сушите.

Освен това при съхранение PPS-CF нишки, важно е да ги поставите в запечатан контейнер със сушител и да се уверите, че относителната влажност вътре в контейнера е под 20% RH.

2.Препоръчителни параметри за печат и аксесоари за печат на PPS-CF

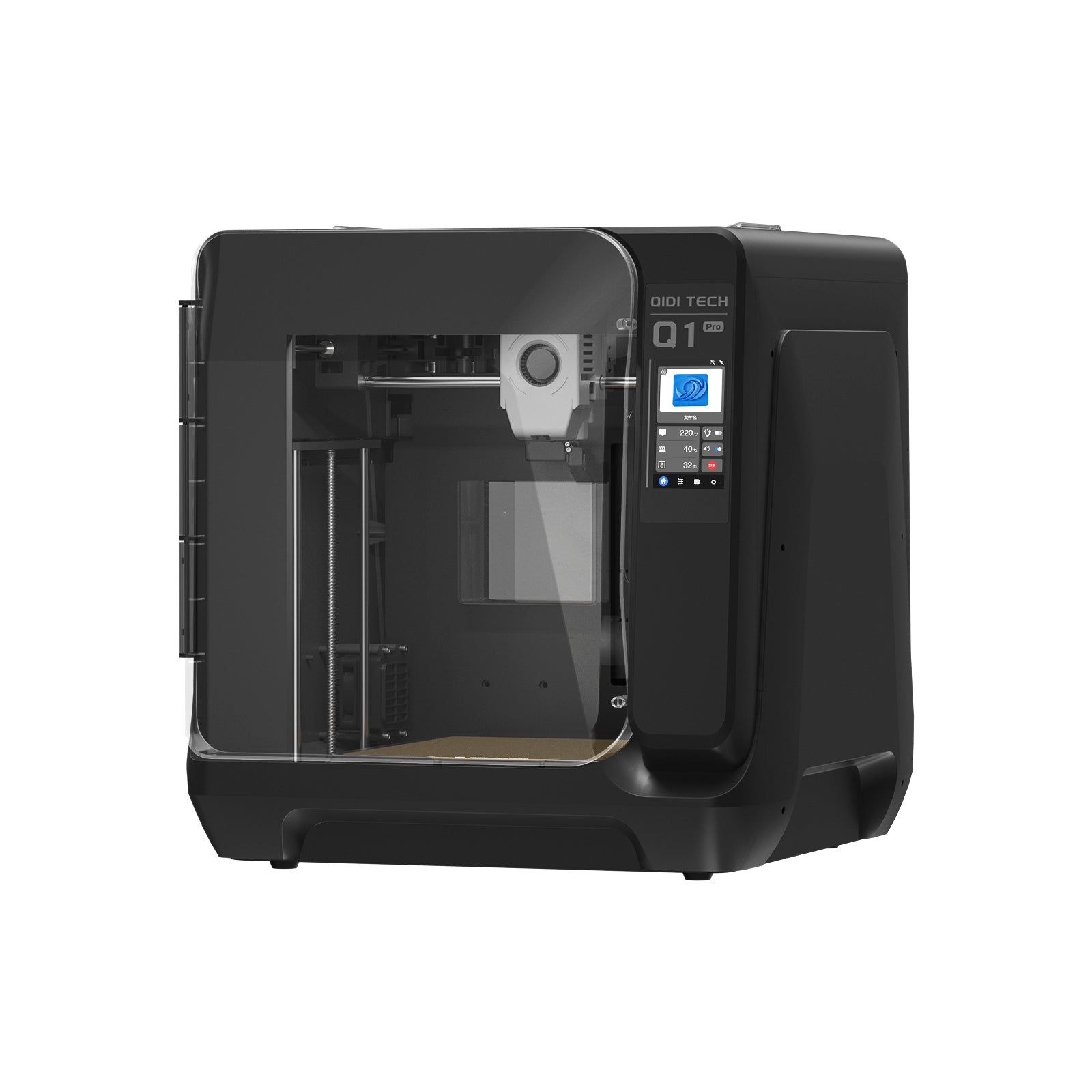

Когато използвате PPS-CF печат с нишка, за да се осигури успешен печат и качество на печат, препоръчваме на потребителите да използват следните аксесоари и параметри на печат (използвайки QIDI плюс 4 като пример):

Препоръчителни аксесоари:

- Плоча за изграждане:Плоча QIDI PEI 、Гладка плоча

- Hotend: Дюза от закалена стомана (0,4 / 0,6 / 0,8 mm) или Биметална дюза (0,4 / 0,6 / 0,8 mm)

- Кутия за сушене: по време на печат, моля, поставете нишките в кутия за сушенеза да предотвратите влиянието на мокрите нишки върху качеството на печат.

Препоръчителни параметри за печат:

- Температура на дюзата: 320-350°C

- Температура на леглото: 100-110°C

- Скорост на печат: 30-100mm/s

- Вентилатор за печат: 0 ~ 30%

3.Как за извършване на отгряване на PPS-CF печатни части?

Отгряването е процес на нагряване и след това охлаждане на материали, за да се променят техните физически свойства. При 3D печата отгряването е ключова стъпка за подобряване на производителността на отпечатаните части чрез елиминиране на термичния стрес за подобряване на здравината, устойчивостта на топлина и т.н.Ефектът от отгряване обаче се влияе от различни фактори като вид на материала, температура на отгряване и продължителност. Особено при сложни модели, неправилната работа може да причини деформация или изкривяване на модела.

За оптимални резултати се препоръчва използването на пещ за сушене на струя.

Подробна обработка на отгряване на PPS-CF печатни части:

- Поставете предметите върху тавата, за да осигурите равномерно нагряване.

- Загрейте кутията до 120 градуса по Целзий.

- Поставете отпечатаните копия в кутията. Оставете да престои и изсъхне повече от 6 часа.

- Изключете сушилнята и оставете предметите да престоят, докато изстинат. Извадете тавата и извадете отпечатаните копия.

4. Какви са предимствата на QIDI PPS-CF?

a. Свръхвисока устойчивост на топлина и пламъци, осигурява надеждна гаранция за използване в ключови области

QIDI PPS-CF има температура на топлинна деформация до 264°C и може да постигне рейтинг за забавяне на горенето UL-94 V-0.

b. Отлична устойчивост на разтворители и химикали, идеална за използване в химическата промишленост

Той е почти неразтворим във всеки разтворител при температури под 200°C и може да устои добре на киселини, основи и соли при нормални условия.

в. Свръхниско водопоглъщане, най-добрият избор за взискателни изисквания за устойчивост на влага

С изключително ниска степен на абсорбция на влага от само 0,05%, QIDI PPS-CF е подходящ за използване във влажна или подводна среда, като работни колела на помпи, морски части и компоненти на оборудване за гмуркане.

г. Отлични механични свойства, отговарящи на изискванията за висока точност

PPS-CF съчетава твърдостта от полифенилен сулфид (PPS) с усилващите способности на въглеродните влакна за осигуряване на отлична твърдост, огъване якост и якост на опън.

QIDI PPS-CF има отлична устойчивост на разтворители, корозия, топлина и пламъци, ултра ниска водопоглъщаемост и отлични механични свойства. Независимо дали в космическото производство, производството на автомобили или в областта на електронното оборудване и химикалите, QIDI PPS-CF показа изключителни перспективи за приложение. Като изберете професионалиста на QIDIНишки за 3D печати отговаряйки на най-новия QIDI Plus4, вие ще застанете в челните редици на технологичните иновации и лесно ще постигнете квазииндустриален клас печатни ефекти. В бъдеще очакваме с нетърпение да проучим повече възможности за печат с вас!