— Най-добрият FDM високоскоростен универсален 3D принтер от индустриален клас —

QIDI Tech

X-MAX 3

-По-бърза скорост 600 мм/сек

-По-голям от по-голям

-325*325*315 мм

-Висок дебит 35 мм³/сек

-Ускорение: 20000 мм/с²

MAX 3 конфигурира гореспоменатите технологии за наистина бърз печат

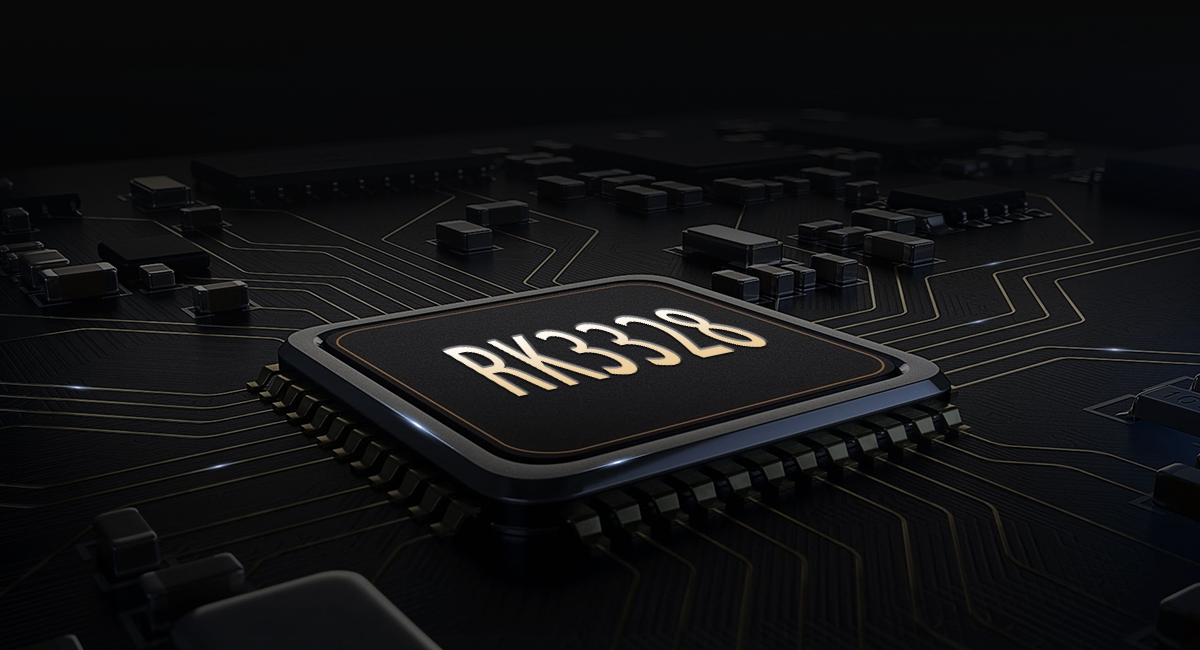

КЛИПЕР

64-битов

Процесор

Cortex-A53

Основна честота 1.5GHz, 8G-EMMC и 1G DDR3

Нова изцяло метална рамка

Ултрастабилна, подсилена с метални напречни греди в долната част, устойчива на деформация.

Линейна куха оптична ос от висококачествена твърда стомана

Подобрена праволинейност на повърхността и 60% по-ниска грешка при отклонение.

Високо издръжлив и без нужда от честа поддръжка.

Обикновено издържат цял живот, без да е необходима подмяна.

Високо издръжлив и без нужда от честа поддръжка.

Обикновено издържат цял живот, без да е необходима подмяна.

Структура на CoreXY

Намалете инерцията на движението и подобрете скоростта на движение.

TMC2209 безшумно задвижване с по-малко шум.

TMC2209 безшумно задвижване с по-малко шум.

Нова охладителна система

Намаляване на риска от запушвания и осигуряване на гладко екструдиране.

Предавателно число 9.5:1

По-стабилна, мощна и по-бърза екструзия.

Два комплекта горещ край

Дюза от медна сплав за по-добра топлопроводимост, плавен печат и по-голяма издръжливост.

Дюза от закалена стомана за абразивни материали и дълготрайна употреба.

И двете 350℃ Максимална температура на печат.

Дюза от закалена стомана за абразивни материали и дълготрайна употреба.

И двете 350℃ Максимална температура на печат.

Камера с контролирана температура

И кутия за сушене

И кутия за сушене

Активно нагревателно устройство

Максимална температура 65℃

Високоефективен печат PET-CF, PAHT-CF и др.

Вентилатор за циркулация на камерата с въздушен филтър с активен въглен.

Максимална температура 65℃

Високоефективен печат PET-CF, PAHT-CF и др.

Вентилатор за циркулация на камерата с въздушен филтър с активен въглен.

Без разделяне на слоевете

Колкото по-висока е температурата в нагрятата камера, толкова по-голям е диапазонът от материали, които могат да бъдат отпечатани. Нагрятата камера гарантира, че детайлът е изработен равномерно, без да се генерират вътрешни напрежения.

Произвеждаме само високоефективни материали

-Професионални материали за печат с индустриално качество-

Автоматично нивелиране

Klipper Adaptive Meshing and Purging, бързо осигурява безупречен първи слой за всеки 3D печат.

Гъвкава HF плоча

Отлична адхезия,

Няма проблеми с деформацията,

Лесно премахване на отпечатъците.

Няма проблеми с деформацията,

Лесно премахване на отпечатъците.

Отлично потребителско изживяване

Високо оцененият софтуер за слайсер QIDI има както нормален, така и експертен режим, което е лесно и за начинаещи!

Ние също така предлагаме Fluidd Console.

За повече информация, моля посетете нашия официална уики (wiki.qidi3d.com).

Спецификации

| Име на машината | |||

| X-Max3 | X-Plus3 | X-Smart3 | |

| Технология | FDM | ||

| Изграждане на обем (Ш×Д×В) | 325*325*315 мм | 280*280*270 мм | 175*180*170 мм |

| Размери (Ш×Д×В) | 553*553*601 мм | 511*527*529 мм | 370*362*397 мм |

| Нетно тегло (кг) | 30.2 | 24.3 | 10.5 |

| Скорост на печат | ≤600 мм/с | ≤500 мм/с | |

| Поток на екструдера: | 35 мм³/сек @PLA Matte (Модел: 150*150 мм единична стена; Материал: PLA Rapido Matte; Температура: 240℃) | 30 мм³/сек | |

| Температура на екструдера | ≤350°C | ≤300°C | |

| Хотенд (включен) | Дюза от медна сплав, гореща част За обикновени материали | Месингова дюза хотенд | |

| Закалена стоманена дюза За абразивни материали | |||

| Вентилатор за охлаждане на спомагателна част | ✔ | ✔ | ✖ |

| Контрол на температурата в камерата | 65°C Независимо отопление на камерата | 65°C Независимо отопление на камерата | ✖ |

| Вентилатор за циркулация на камерата С въздушен филтър с активен въглен | ✔ | ✔ | Вентилатор за циркулация на камерата |

| Екран | 5,0 инча | 4,3 инча | |

| 800*480 сензорен екран | 480*272 сензорен екран | ||

| Печат на печат | Кутия за сушилня + десикант | По избор | |

| Опции за свързване | 150M 2.4G Wi-Fi USB флаш устройство/Ethernet кабел | 150M 2.4G Wi-Fi USB флаш устройство | |

| Номинална мощност | 900W | 800W | 350W |

| Препоръчителен филамент | PAHT-CF, PET-CF, PA12-CF | PLA | |

| Съвместим филамент | PLA, ABS, ASA, PETG, TPU, PC, UltraPA, найлон и др. | ABS, ASA, PETG, TPU и др. | |

| Структура | CoreXY | ||

| Z-ос: | Двойна Z ос | ||

| X ос | Линейна куха оптична ос от висококачествена твърда стомана | Закалена износоустойчива пръчка от въглеродни влакна | |

| Фърмуер: | Клипер | ||

| Ускорение на печат: | 20000 мм/сек² | ||

| Точност на печат: | ±0,1 мм | ||

| Диаметър на нишката: | 1,75 мм | ||

| Нивелиране на леглото: | Автоматично нивелиране | ||

| Предавателно съотношение на екструдера | 9,5:1 | ||

| Горещ край: | Керамично нагревателно ядро | ||

| Екструдер: | Екструдер с директно задвижване с висок поток | ||

| Диаметър на дюзата: | 0,4 мм (0,2, 0,6, 0,4 мм)8 мм (по избор) | ||

| Температура на горещото легло: | ≤120℃ | ||

| Печатна плоча: | Двустранна гъвкава магнитна плоча | ||

| Откриване на филаменти: | Да | ||

| Резонансна компенсация: | Да | ||

| Напредване на налягането: | Да | ||

| Напрежение: | 100-240VAC, 50/60Hz | ||

| Главен процесор: | Cortex-A53, 64-битов процесор | ||

| 1.5Ghz, 8G-EMMC, 1G DDR3 | |||

| Слайсер: | QIDI Print и друг софтуер на трети страни, като Ultimaker Cura, Simplify3D, PrusaSlicer и др. | ||

| Операционна система: | Windows, MacOS, Linux | ||

| Сглобено | Сглобяване и първи отпечатък в рамките на 10 минути | ||

| Научете повече | Научете повече | Научете повече | |

| Име на машината | ||

| X-Max3 | X-Plus3 | X-Smart3 |

| Технология:FDM | ||

| Обем на конструкцията (Ш×Д×В мм) | ||

| 325*325*315 | 280*280*270 | 175*180*170 |

| Размери (Ш×Д×В мм) | ||

| 553*553*601 | 511*527*529 | 370*362*397 |

| Нетно тегло (кг) | ||

| 30.2 | 24.3 | 10.5 |

| CoreXY | ||

| Z-ос:Двойна Z ос | ||

| Ос X: Линейна куха оптична ос от висококачествена твърда стомана | Ос X: Закалена износоустойчива пръчка от въглеродни влакна | |

| Фърмуер:Клипер | ||

| Скорост на печат | ||

| ≤ 600 мм/с | ≤ 500 мм/с | |

| Поток на екструдера: | ||

| 35 мм³/сек @PLA Matte (Модел: 150*150 мм единична стена; Материал: PLA Rapido Matte; Температура: 240℃) | 30 мм³/сек | |

| Ускорение на печат:20000 мм/сек² | ||

| Точност на печат:± 0,1 мм | ||

| Температура на екструдера | ||

| ≤350℃ | ≤300℃ | |

| Диаметър на нишката:1,75 мм | ||

| Нивелиране на леглото: Автоматично нивелиране | ||

| Предавателно съотношение на екструдера:9,5:1 | ||

| Горещ край: Керамично нагревателно ядро | ||

| Екструдер:Екструдер с директно задвижване с висок поток | ||

| Дюза | ||

| Дюза от медна сплав (За обикновени нишки) Дюза от закалена стомана (За абразивни филаменти) | Месингова дюза | |

| Диаметър на дюзата | ||

| 0,4 мм (0,2, 0,6, 0,4 мм)8 мм (по избор) | ||

| Температура на горещото легло: ≤120℃ | ||

| Печатна плоча:Двустранен гъвкав магнитен Чиния | ||

| Вентилатор за охлаждане на спомагателна част | ||

| ✔ | ✔ | ✖ |

| Контрол на температурата в камерата | ||

| 65°C Независимо отопление на камерата | ✖ | |

| Вентилатор за циркулация на камерата С въздушен филтър с активен въглен | ||

| ✔ | ✔ | Вентилатор за циркулация на камерата |

| Екран | ||

| 5,0 инча 800*480 сензорен екран | 4,3 инча 480*272 сензорен екран | |

| Печат на печат | ||

| Кутия за сушилня + десикант | По избор | |

| Опции за свързване | ||

| 150M 2.4G Wi-Fi USB флаш устройство/ Ethernet кабел | 150M 2.4G Wi-Fi USB флаш устройство | |

| Откриване на нишки: Да | ||

| Резонансна компенсация: Да | ||

| Предварително налягане:Да | ||

| Напрежение:100-240VAC, 50/60Hz | ||

| Номинална мощност | ||

| 900W | 800W | 350W |

| Главен процесор:Cortex-A53, 64-битов процесор 1.5Ghz, 8G-EMMC, 1G DDR3 | ||

| Слайсер | ||

| QIDI Slicer и друг софтуер на трети страни, като например Ultimaker Cura, Simplify3D, PrusaSlicer и др. | ||

| Операционна система: Windows, MacOS, Linux | ||

| Препоръчителен филамент | ||

| PAHT-CF, PET-CF, PA12-CF | PLA | |

| Съвместим филамент | ||

| PLA, ABS, ASA, PETG, TPU, PC, UltraPA, найлон и др. | ABS, ASA, PETG, TPU и др. | |

| Сглобяване и първи отпечатък в рамките на 10 минути | ||

| Научете повече | Научете повече | Научете повече |

Q2

Q2

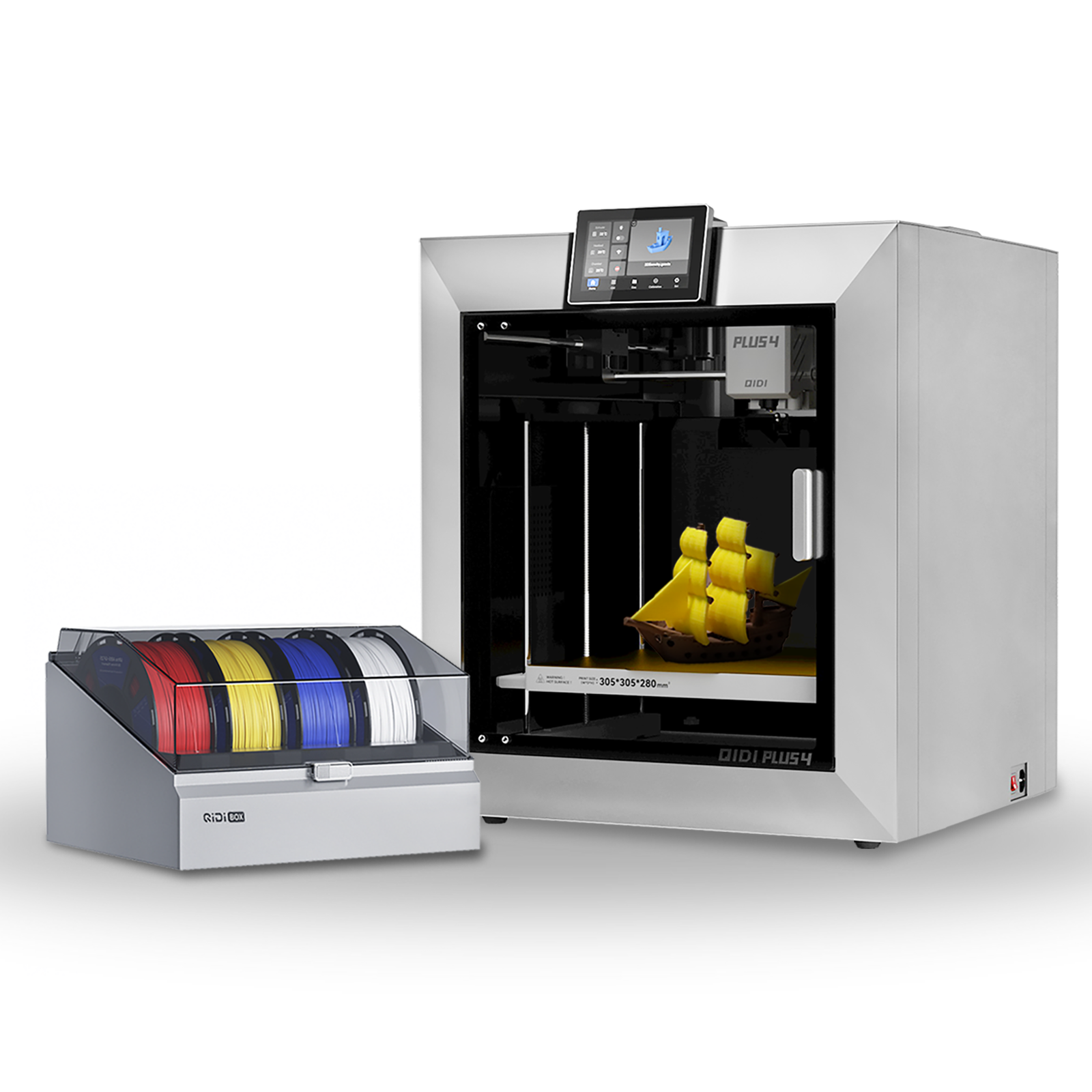

Plus4

Plus4

Qidi Box

Qidi Box

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/3034a1133efe01daba919094b70c6310.jpg?v=1750300120) Q1Pro

Q1Pro

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1750300138) Max3

Max3

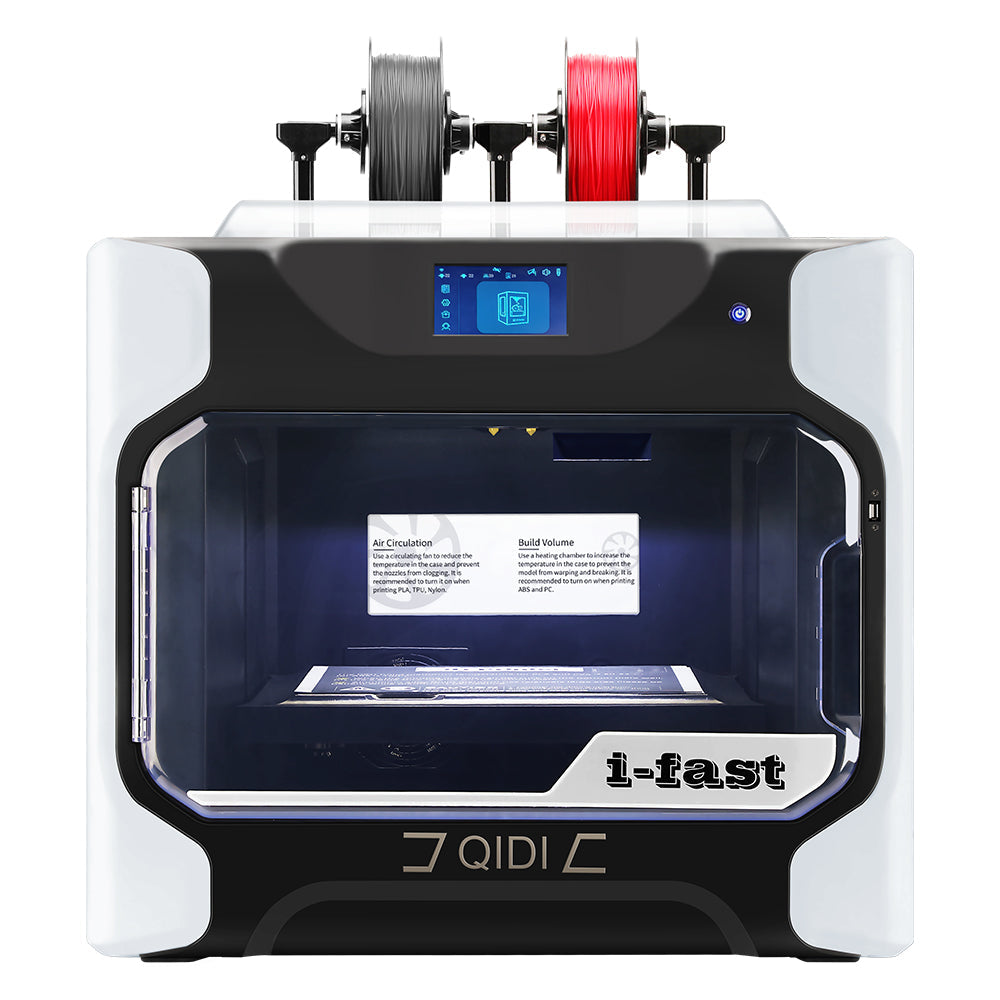

I-Fast

I-Fast

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1750300138&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-buildvolume.jpg?v=1756110092&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-SPEED.jpg?v=1756110092&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-ALL-round.png?v=1756110092&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-all-metal.jpg?v=1756110092&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-6.jpg?v=1756110092&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/Max3-AUTO-leveling.jpg?v=1756110092&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-7.jpg?v=1756110092&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-01.png?v=1756110092&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1750300138&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-buildvolume.jpg?v=1756110092&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-SPEED.jpg?v=1756110092&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-ALL-round.png?v=1756110092&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-all-metal.jpg?v=1756110092&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-6.jpg?v=1756110092&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/Max3-AUTO-leveling.jpg?v=1756110092&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-7.jpg?v=1756110092&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-01.png?v=1756110092&width=540)