Ultrapa-CF25 (PPA-CF πυρήνα) νήμα)

Χαρακτηριστικά προϊόντος

- Εξαιρετικές μηχανικές ιδιότητες

- Υψηλή διαστατική σταθερότητα

- Εξαιρετική θερμική αντίσταση

- Εξαιρετική πρόσφυση στρώσεων

Προφυλάξεις κατά τη χρήση

Ακροφύσιο 0,2 mm Μη συμβατό

Πρέπει να στεγνώσει πριν από τη χρήση για να επιτευχθεί βέλτιστη ποιότητα εκτύπωσης

- Σε απόθεμα, έτοιμο για αποστολή

- Backrorder, αποστολή σύντομα

Οι τιμές αποστολής ποικίλλουν ανάλογα με την τοποθεσία. Δείτε τα προϊόντα μας. Πολιτική αποστολής για λεπτομέρειες.

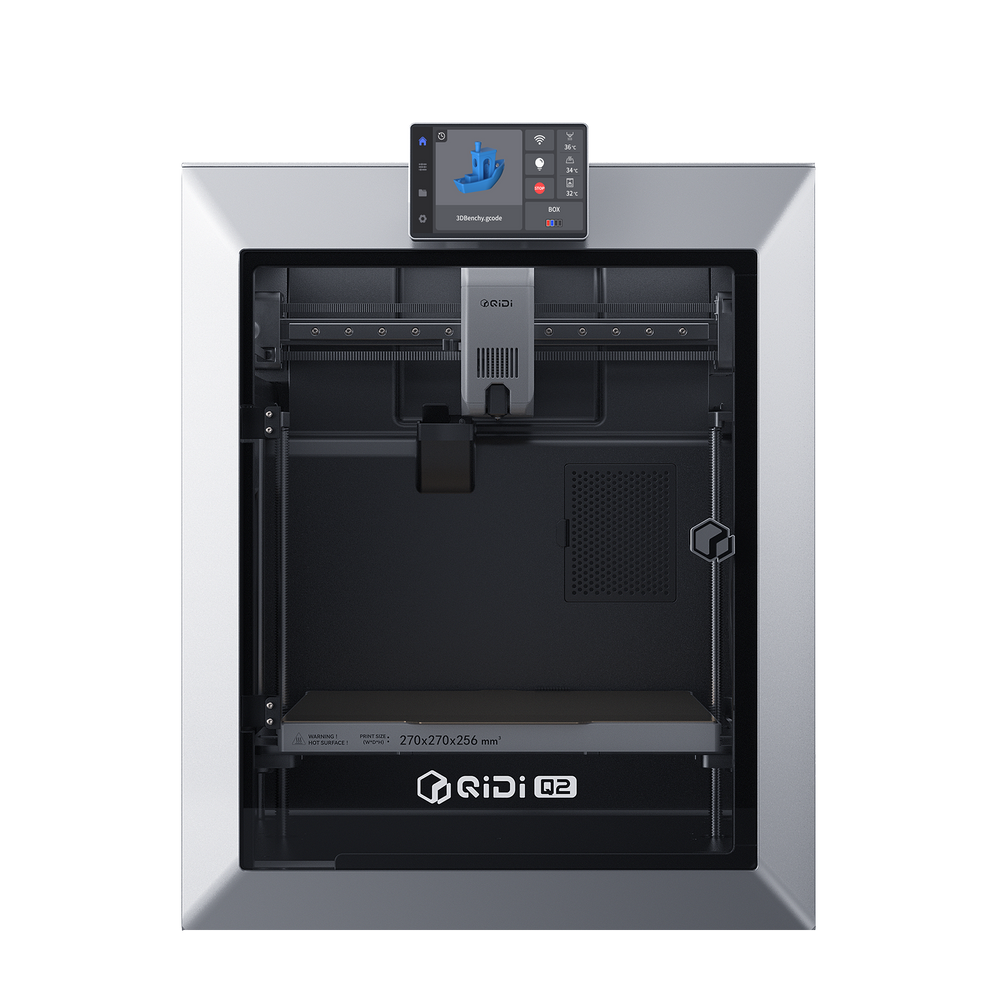

Q2

Q2

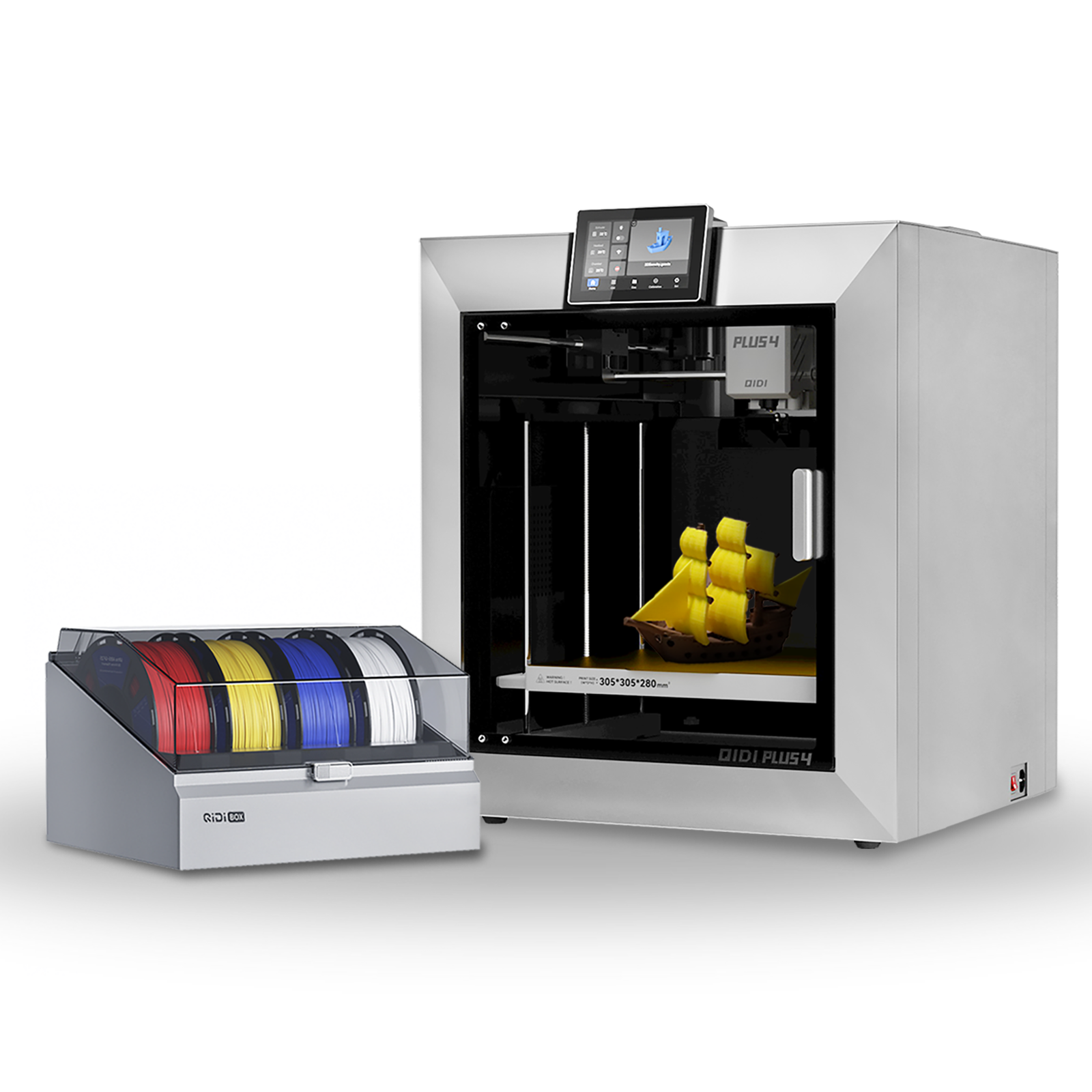

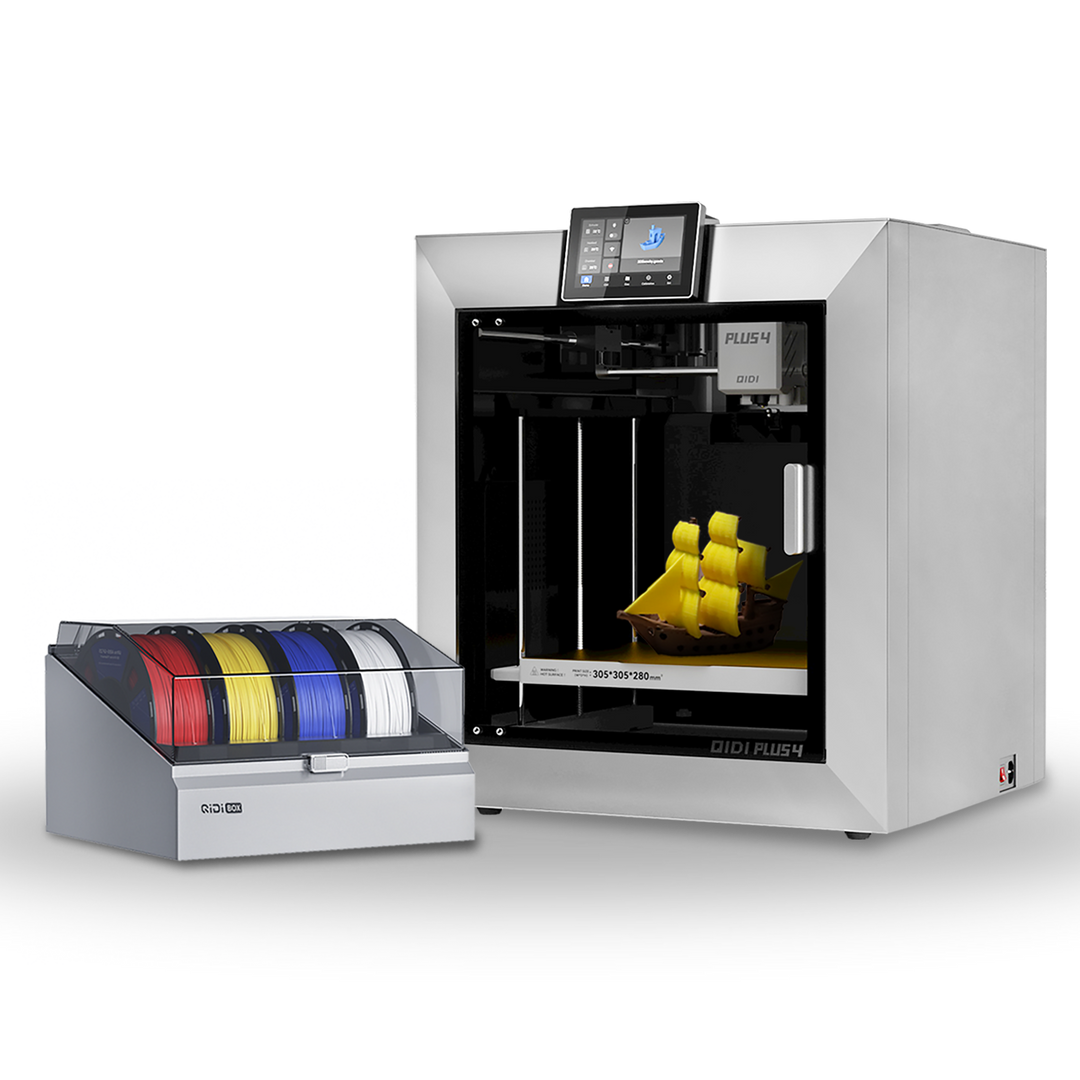

Plus4

Plus4

Κουτί QIDI

Κουτί QIDI

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/3034a1133efe01daba919094b70c6310.jpg?v=1750300120) Q1Pro

Q1Pro

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1750300138) Max3

Max3

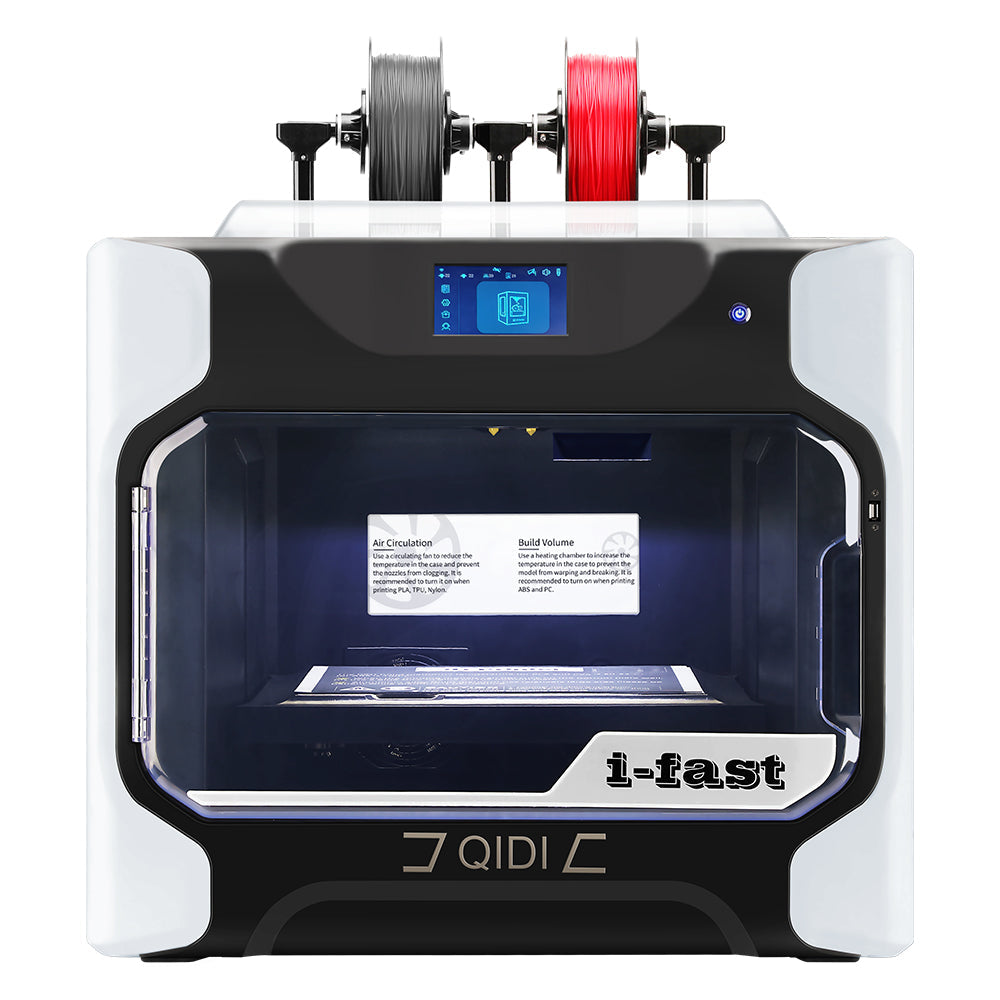

I-Fast

I-Fast

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1750300138&width=1080)