3D printera pirkšanas rokasgrāmata

Atrodiet perfekto 3D

printeris jūsu projektiem.

Sāc savu radošo piedzīvojumu jau šodien!

Atdzīviniet savas idejas ar Qidi FDM 3D printeriem

Kausētās nogulsnēšanas modelēšana (FDM) ir izplatīta 3D drukāšanas tehnoloģija, kas ir QIDI piedāvājumu pamatā.FDM 3D printeridarbojas, uzkarsējot termoplastiskās šķiedras līdz pusšķidram stāvoklim un precīzi nogulsnējot tās slāni pa slānim uz veidošanas platformas, vadoties pēc digitāla 3D modeļa. Šis aditīvās ražošanas process ļauj izveidot sarežģītus trīsdimensiju objektus ar augstu precizitāti un atkārtojamību.

FDM printeri ir viens no populārākajiem 3D printeru veidiem mūsdienu tirgū. Šāda veida 3D printeriem ir laba materiālu saderība un lietotājam draudzīgas lietojumprogrammas.

Materiāla daudzpusība: FDM 3D printeri atbalsta dažādu termoplastisku materiālu, tostarp PLA, ABS, PETG, TPU utt., izmantošanu. Katram materiālam ir unikālas īpašības, piemēram, izturība, elastība, karstumizturība un caurspīdīgums, un jūs varat izvēlēties sev piemērotāko. 3D drukāšanas materiāls atbilstoši jūsu konkrētajam pielietojumam.

Izmaksu efektivitāte: Salīdzinot ar citām 3D drukāšanas metodēm, FDM tehnoloģija parasti ir pieejamāka. FDM printeru izmaksas ir salīdzinoši zemas, un arī izejvielu (kvēldiegu) cena ir saprātīga. Tas padara FDM par dzīvotspējīgu izvēli hobijiem, pedagogiem un maziem un vidējiem uzņēmumiem.

Viegli lietojams un kopjams: Mūsu FDM printeri ir aprīkoti ar vienkāršu un skaidru vadības paneli, kas ļauj iesācējiem viegli kontrolēt printera pamatfunkcijas, nospiežot pogas vai pagriežot kloķus. Darbības process ir intuitīvs un viegli saprotams. Apkope ir arī vienkārša, galvenokārt ietverot regulāru tīrīšanu, sprauslu nomaiņu un neregulāru kalibrēšanu.

FDM 3D printeri tiek izmantoti daudzās jomās., tostarp:

Ikdienas vajadzības: Apdrukājiet mājsaimniecības priekšmetus, piemēram, mobilo tālruņu maciņus, atslēgu piekariņus, paliktņus, garšvielu burku turētājus un biroja piederumus, piemēram, dokumentu glabāšanas kastes un peles paliktņus.

Mākslinieciski un dekoratīvi elementi: Izmanto skulptūru, tostarp abstraktu skulptūru un skulptūru ar noteiktām tēmām, veidošanai, kā arī unikālu rotaslietu, piemēram, auskaru un kaklarotu kulonu, izgatavošanai.

Izglītības modeļi: Izveidojiet mācību modeļus, piemēram, cilvēka orgānu modeļi bioloģijas stundās, topogrāfiskie modeļi ģeogrāfijas stundās un ģeometriskie modeļi matemātikas stundās.

Industriālie prototipi & Pielāgotas detaļas: Izdrukājiet produktu prototipus izskata un funkcionalitātes pārbaudei produktu izstrādes sākumposmā, kā arī drukājiet pielāgotas detaļas īpašām rūpnieciskām iekārtām.

Medicīniskā & Veselības aprūpes lietojumprogrammas: Izgatavojiet pielāgotas ortopēdiskās ierīces, piemēram, arkas atbalsta spilventiņus un ķirurģiskās vadotnes, lai palīdzētu mutes dobuma vai ortopēdiskajā ķirurģijā.

Ja neesat pārliecināts, kurš 3D printeris jums ir piemērots, vispirms varat noskaidrot drukāšanas mērķi vai uzdevumu:

Drukāšanas mērķis

Patērētāja līmenis (personīgais/ģimenes): piemērots mazu modeļu, radošu dizainu drukāšanai un parasti ar mazāku budžetu, piemēram, Qidi Tech Q1 Pro.

Profesionālais līmenis (izglītība/laboratorija): jāņem vērā gan precizitāte, gan stabilitāte, kas atbalsta ātrdarbīgu drukāšanu un automātisko izlīdzināšanu.

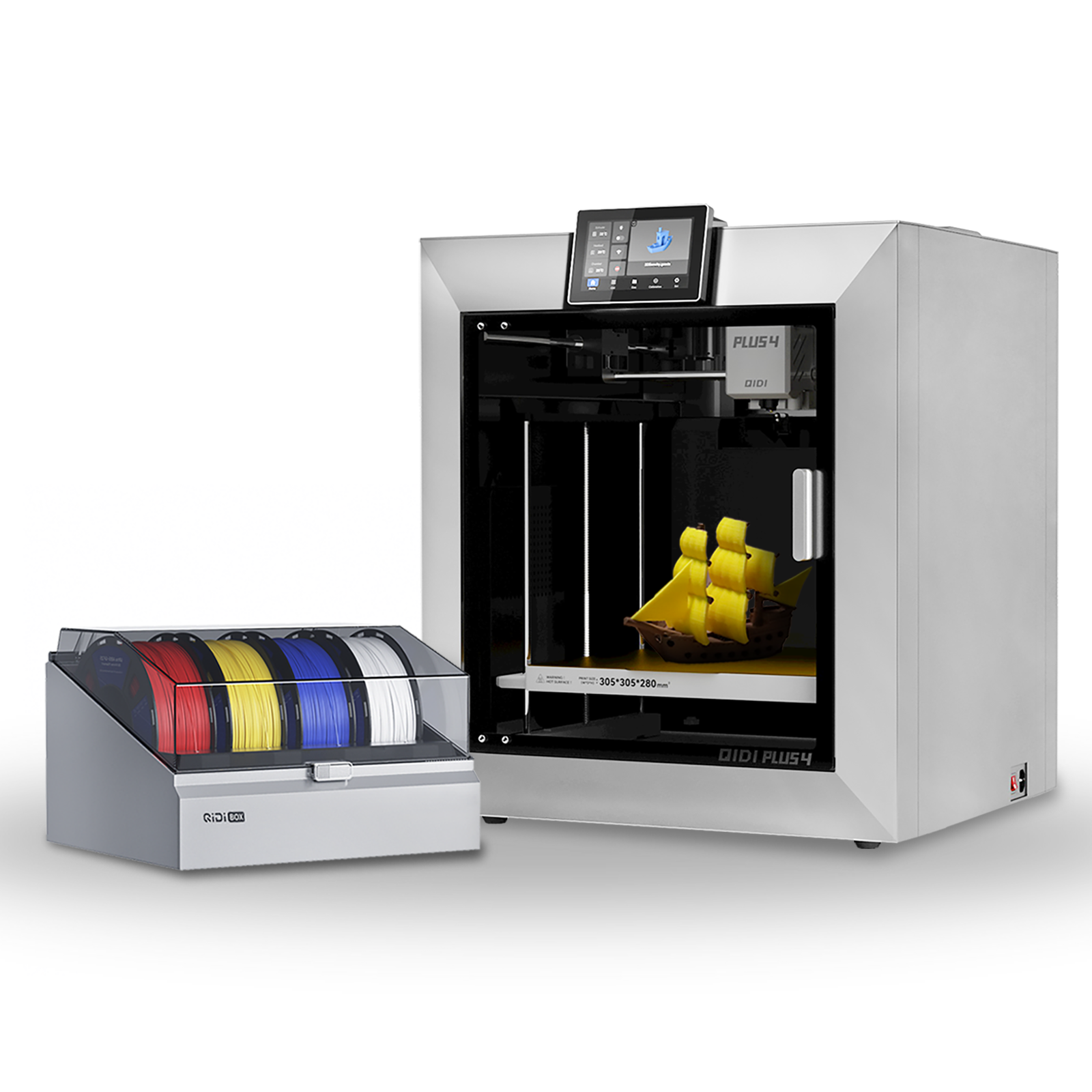

Rūpnieciskā (ražošana/izgatavošana) printeri, piemēram, QIDI Plus4 ir paredzēti augstas intensitātes ražošanai. Tam ir liels drukāšanas apjoms lielu projektu apstrādei. QIDI Plus4 apsildāmās kameras temperatūra ir 65 °C, un tas atbalsta augstas temperatūras izturīgus materiālus, kas palīdz sasniegt augstas kvalitātes izdrukas.

Drukāšanas mērķis

Modeļa izmērs: Rūpnieciskajam līmenim nepieciešams liels konstrukcijas izmērs, savukārt patērētāja līmenim galvenokārt ir nepieciešams 200–300 mm³.

Materiālu saderība: Ja jums ir nepieciešams drukāt inženiertehniskās plastmasas (ABS, neilons) vai kompozītmateriāli (ar oglekļa šķiedru pastiprināti), jums jāizvēlas modelis, kas atbalsta augstas temperatūras sprauslas un slēgta struktūra.

Varat arī aplūkot tādus veiktspējas parametrus kā drukas precizitāte. Drukas precizitāti mēra ar tādiem faktoriem kā slāņa augstums un sprauslas diametrs. Mazāks slāņu augstums un sprauslu diametrs parasti nodrošina augstākas izšķirtspējas izdrukas ar smalkākām detaļām. Ja jūsu projektam ir nepieciešamas augstas precizitātes detaļas, meklējiet printeri, kas var sasniegt mazākus slāņu augstumus un kam ir mazākas sprauslu iespējas.

FAQ

Atrodiet atbildes uz vissteidzamākajiem jautājumiem par mūsu 3D drukāšanas mašīnām un pakalpojumiem.

FDM 3D printeris, kas pazīstams arī kā kausēti nogulsnēšanas modelēšanas printeri, ir printeris, kas veido objektus caur izkausēta plastmasas kvēldiega nogulsnēšanos pa slāni. Plastmasas pavedienu karsē, līdz tas izkausē un izspiež caur sprauslu, lai veidotu interesējošo formu. Viens no iemesliem, kāpēc FDM printeri ir populāri, ir tas, ka tie ir lēti un ļoti viegli lietojami, tāpēc tos plaši izmanto gan iesācēji, gan profesionāli lietotāji.

FDM 3D printeriem ir vairākas priekšrocības. Pirmais ir tas, ka tie parasti ir rentablāki nekā cita veida 3D drukas tehnoloģijas. Šī ekonomika padara tos pieejamus plašam tirgum, piemēram, hobijiem, pedagogiem un profesionāļiem. Otrkārt, FDM printeri ir draudzīgi lietotājam un tie ietver plašu materiālu klāstu, sākot no grūtām līdz inženiertehniskai termoplastikai, piemēram, ABS un PLA. Šie printeri ir daudzpusīgi, kas ļauj tos izmantot plašā lietojumprogrammu diapazonā, sākot no prototipēšanas līdz funkcionālo detaļu izstrādei. Izgatavotās detaļas ir spēcīgas, un tās var izturēt mehānisku izmantošanu. Arī skriešanas izmaksas ir zemas, jo tām nav vajadzīgas nekāda veida bīstamas ķīmiskas vielas, padarot to drošu un ērtu palaišanu.

FDM 3D drukāšanas process ietver 3D modeļa izstrādi, izmantojot CAD programmatūru. Pēc tam, kad jūsu dizains ir gatavs, sagriešanas programmatūru izmanto, lai pārveidotu modeli dažādos slāņos. Pēc tam printeris silda plastmasas pavedienu un izspiež to caur sprauslu, katru slāni noliekot saskaņā ar sagrieztu modeli. Tā kā slānis ir nolikts, tas atdziest un sacietē, veidojot galīgo objektu. Šis slāņa mehānisms nodrošina kontroli pār galīgā objekta formu un struktūru.

SLA un FDM ir divas dažādas 3D drukas tehnoloģijas. Galvenā atšķirība ir materiāls un process. FDM printeri izmanto termoplastiskus pavedienus, kas ir izkusuši un ekstrudēti, lai noliktu slāņus. SLA printeri izmanto šķidros sveķus, kurus izārstē ar lāzeru, lai izārstētu katru slāni. SLA parasti ir ar labāku izšķirtspēju, un virsmas ir vienmērīgākas, tāpēc tā ir ļoti piemērota dizainam ar daudz detaļām un ļoti sarežģītām. FDM ir piemērotāks funkcionāliem prototipiem un lielākām detaļām, jo tas ir stiprāks un lētāks. Parasti FDM ir arī lētāks, salīdzinot ar SLA printeriem un to materiāliem.

Drukas izšķirtspēja, slāņa augstums, ekstrūdera un platformas temperatūra, drukas ātrums, kvēldiega kvalitāte, sprauslas lielums un pareizie šķēles iestatījumi ietekmē galīgo drukas kvalitāti. Divkārša ekstrūzija, slēgta uzbūves kamera un automātiskās kalibrēšanas funkcijas arī palīdz uzlabot konsekvenci, precizitāti un uzticamību.

Q2

Q2

Plus4

Plus4

Qidi kaste

Qidi kaste

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/3034a1133efe01daba919094b70c6310.jpg?v=1750300120) Q1Pro

Q1Pro

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1750300138) Max3

Max3

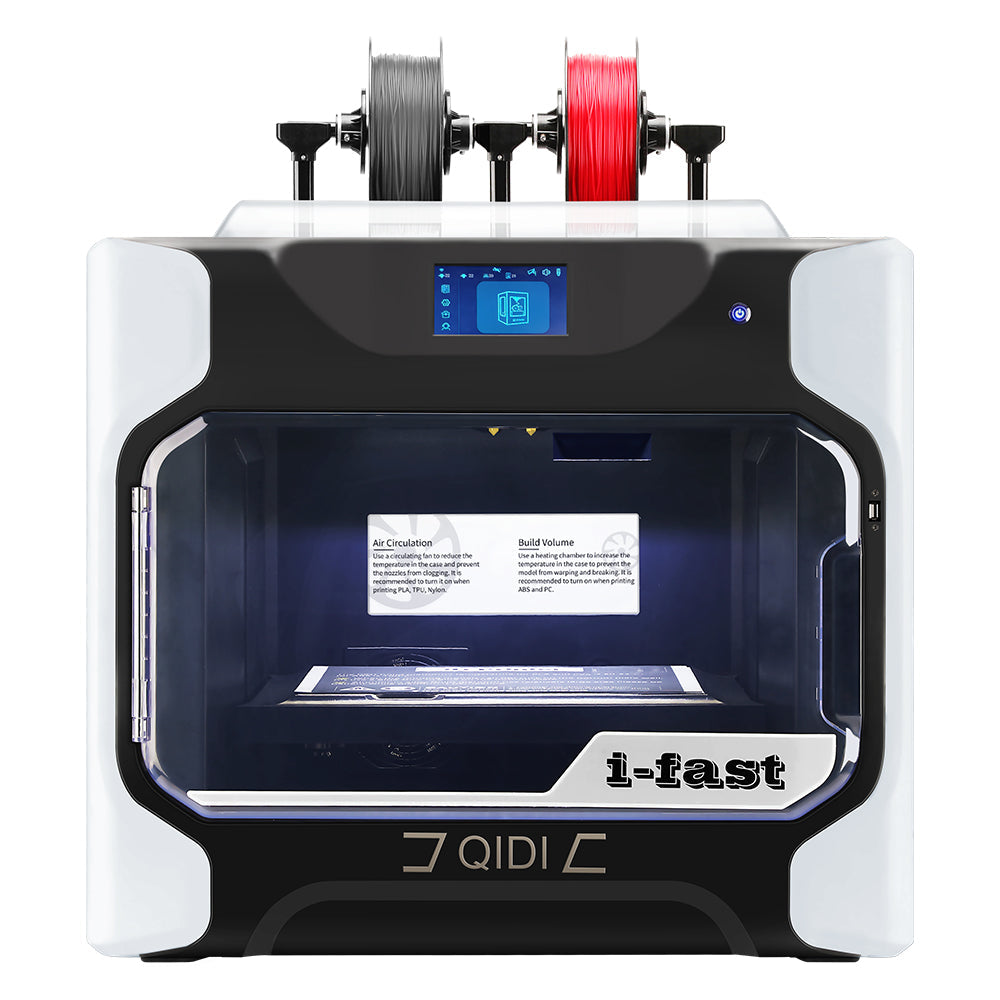

Es ātri

Es ātri