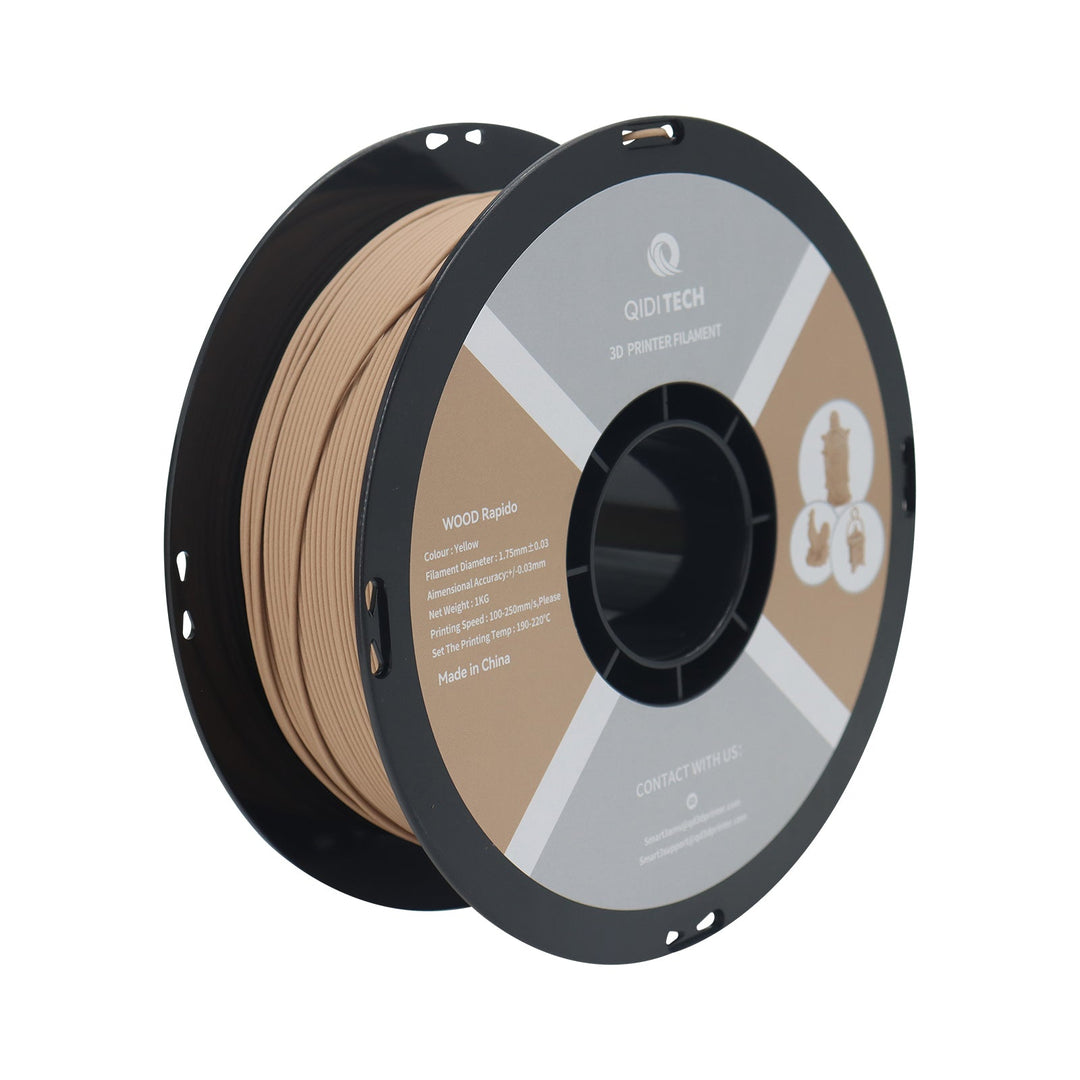

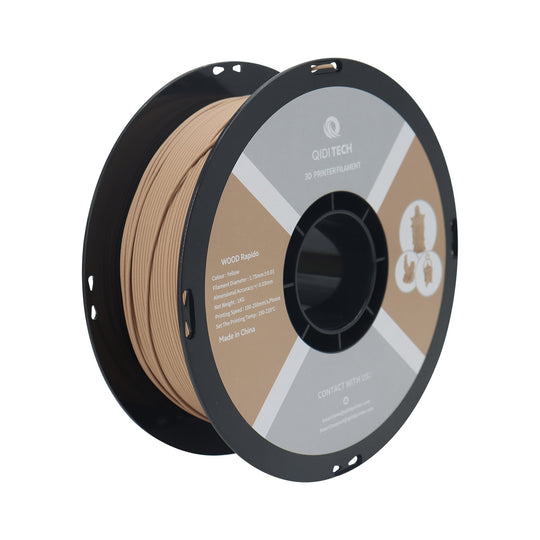

QIDI PLA Træ 3D-printerfilament

Mat tekstur | Trælignende effekt | Indeholder 10% naturlige træfibre

Forførende mat trælignende tekstur

Denne matte finish giver ikke kun et rustikt og charmerende udseende, men giver også en bedre taktil oplevelse, der får de trykte genstande til at føles mere som ægte trægenstande.

Speciel dispersionsproces

Denne præcise spredning sikrer en ensartet blanding, hvilket igen fører til forbedrede mekaniske egenskaber og dimensionsstabilitet af de trykte objekter.

Fuldt biobaserede og miljøvenlige formuleringer

Giver brugerne mulighed for at skabe deres ønskede mesterværk, samtidig med at de er bevidste om deres økologiske påvirkning og bidrager til en grønnere fremtid.

Farvedisplay

To valgmuligheder for træfarver giver dig fleksibiliteten til at skabe din unikke kunstneriske vision.

Produktstørrelse

QIDI PLA træfilament 1,75 mm. Fungerer perfekt med de fleste FDM 3D-printere på markedet.

Tilbehørskompatibilitet

| Anbefalet | Ikke anbefalet | |

| Byggeplade | QIDI PEI-plade, HF-plade, PC-plade og glat plade | / |

| Hotend | Hærdet ståldyse (0,4/0,6/0,8 mm) Bimetaldyse (0,4/0,6/0,8 mm) | Messing-/kobberbelagt dyse (0,2/0,4/0,6/0,8 mm) |

| Lim | Limstift/3D LAC klæbespray | / |

| Anbefalede udskrivningsindstillinger | |

| Tørreindstillinger (blæsttørreovn) | 50 °C, 4-6 timer |

| Udskrivning og opbevaring af beholderens fugtighed | < 15% RF (forseglet, med tørremiddel) |

| Dysetemperatur | 190-220 °C |

| Sengtemperatur (med lim) | 30-60 ℃ |

| Udskrivningshastighed | 40-200 mm/s |

| Fysiske egenskaber | |

| Tæthed | 1,22 - 1.24 g/cm³ |

| Vicat blødgøringstemperatur | 58 °C |

| Varmeafbøjningstemperatur | 57 °C |

| Smeltetemperatur | - 160 °C |

| Smeltestrømningshastighed | 7-12 g/10 min |

| Mekaniske egenskaber | |

| Trækstyrke | 25-28 MPa |

| Brudstyrke | 10-8 % |

| Bøjningsmodul | 4200-4600 MPa |

| Slagstyrke | 12-15 kJ/m² |

Udskrivningstips

Med tilsætning af naturligt træpulver udviser PLA-træ følgende forskellige egenskaber sammenlignet med almindelig PLA.

1. Højere fugtabsorption: PLA-træ indeholder naturligt træpulver, hvilket gør det mere følsomt over for fugt. Tør før brug for at sikre den bedste trykkvalitet og ensartet finish.

•Opbevaring og tørring: Selvom PLA-træ tørres grundigt og vakuumforsegles inden forsendelse, kan variationer i transportforholdene påvirke dets fugtighedsniveau. Vi anbefaler kraftigt at tørre det lige efter åbning og opbevare det i en lukket beholder med tørremiddel. Gentag tørring og fugtighedsbeskyttelse før hver langtidsopbevaringsperiode.

•Tørringsvejledning: For at opnå de bedste resultater, tør ved 55 ± 5 °C i 8 timer i en blæsttørreovn.

2. Farvevariation: Naturligt træpulver kan resultere i små farvevariationer afhængigt af tørringsgrad og forskelle i råmaterialer.

3.Trælignende lugt: Under printning udsender PLA Wood en mild, naturlig træduft på grund af indholdet af træpulver. Det er ikke-irriterende og giftfrit.

For yderligere oplysninger henvises til: Filamentguide på WIKI.

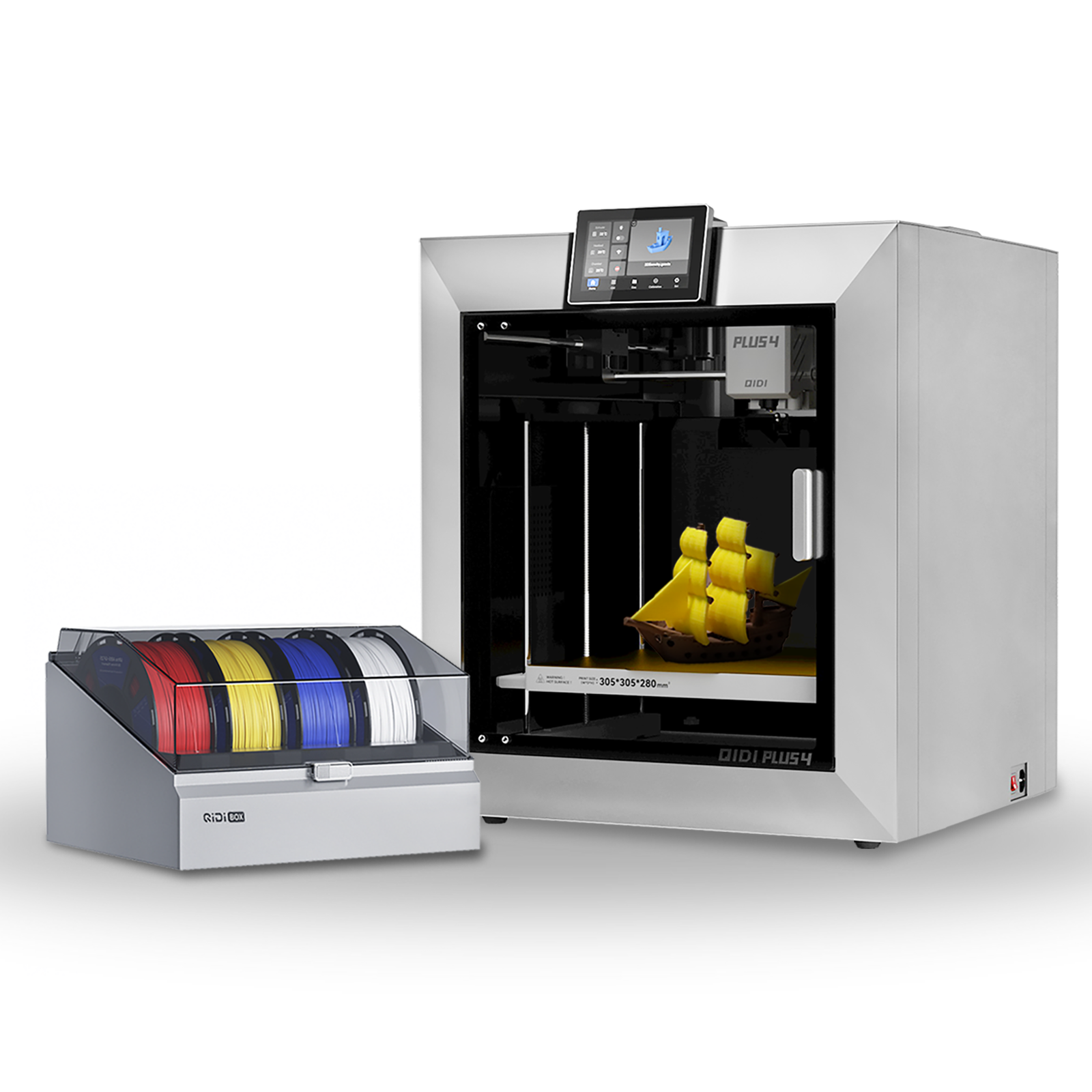

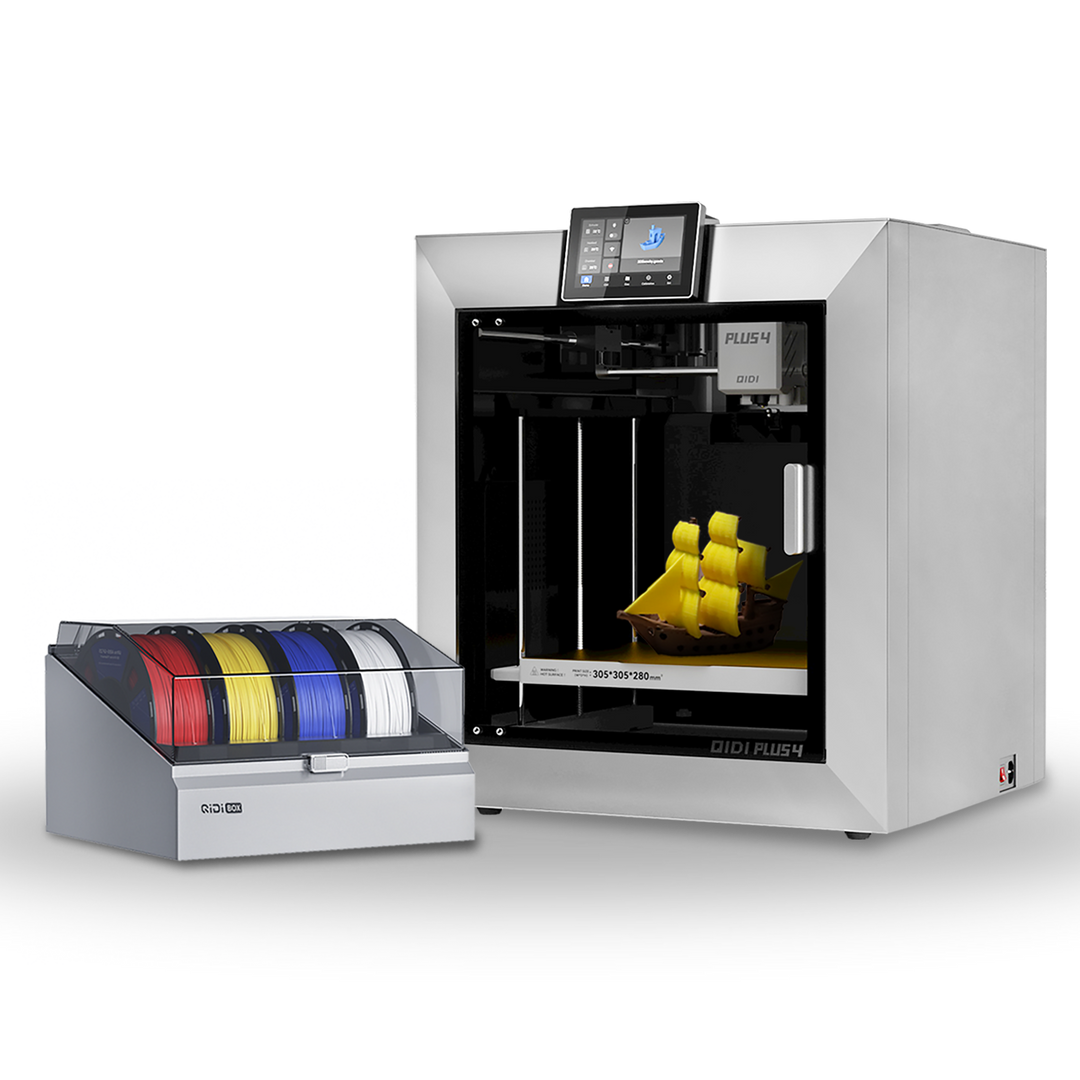

Qidi Plus4 3D -printer

Qidi Plus4 3D -printer

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/3034a1133efe01daba919094b70c6310.jpg?v=1750300120) Qidi Tech Q1 Pro 3D -printer

Qidi Tech Q1 Pro 3D -printer

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1750300138) Qidi Tech X-Max 3 3D-printer

Qidi Tech X-Max 3 3D-printer

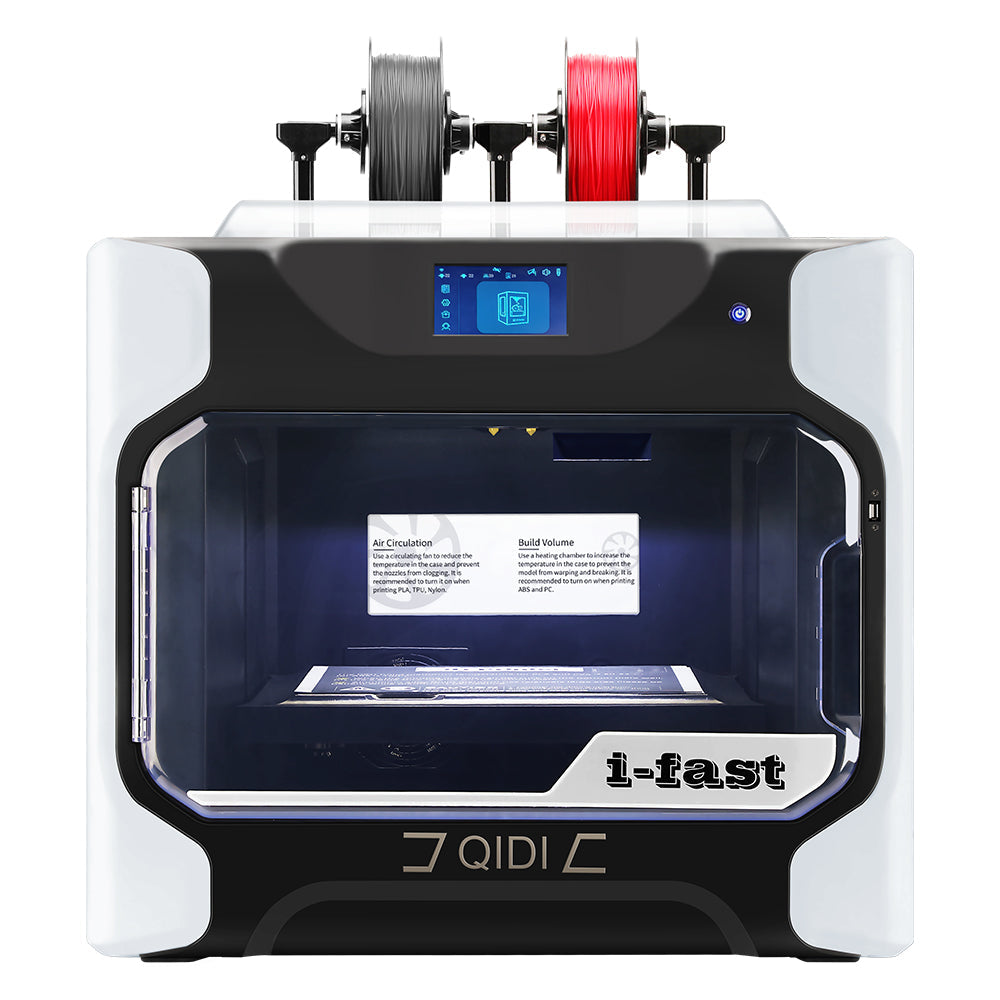

Qidi Tech I-hurtig 3D-printer

Qidi Tech I-hurtig 3D-printer

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1750300138&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/3034a1133efe01daba919094b70c6310.jpg?v=1750300120&width=1080)