QIDI UltraPA 3D Printer Filament

QIDI UltraPA is specially developed for FDM 3D printing process, and its substrate material is high temperature nylon(PPA), which has low density, low moisture absorption, high strength, high abrasion resistance, excellent chemical resistance and high heat resistance.

Low Moisture Sensitivity

QIDI TECH UltraPA based on modified high temperature nylon(substrate material PPA), whose saturated moisture absorption rate is only one fifth of ordinary PA6, completely solving the defects of the mechanical properties and dimensional stability of nylon materials that change greatly after absorbed moisture.

Strongest layer bonding performance

QIDI UltraPA have the best layer strength,the layer adhesion of single wall structure is 2-3 times of ABS material and 1.5 times of PLA material.

Super Abrasive Resistance

QIDI UltraPA has low coefficient of friction, self-lubricating properties and excellent wear resistance,which can easily meet all kinds of high-strength gears or industrial applications with high wear requirements.

Accessory Compatibility

| Recommended | Not Recommended | |

| Build Plate | QIDI PEI Plate, HF Plate and Smooth Plate | PC Plate |

| Hotend | Hardened Steel Nozzle ( 0.4 / 0.6 / 0.8 mm) Bimetal Nozzle ( 0.4 / 0.6 / 0.8 mm) |

Brass/Copper plated Nozzle (0.2/0.4/0.6/0.8 mm) |

| Glue | PVP glue/ 3D LAC adhesive spray | / |

| Recommended Printing Settings | |

| Drying Settings (Blast Drying Oven) | 80-100 °C,4-6 h |

| Printing and Keeping Container's Humidity | < 15% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 260 - 280 °C |

| Bed Temperature (with Glue) | 70-80 °C |

| Printing Speed | < 30-120 mm/s |

| Physical Properties | |

| Density | 1.21 g/cm³ |

| Water absorption | 2.10 % |

| Heat Deflection Temperature | 72.5 °C |

| Melting Temperature | 231 °C |

| Melt Index | 9.4 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 69.29±1.17 MPa |

| Breaking Elongation Rate | 9.77±1.68 % |

| Bending Modulus | 3202.24±115.78 MPa |

| Bending Strength | 112.64±1.60 MPa |

| Impact Strength | 9.74±0.84 KJ/m2 |

Printing Tips

• Nylon material is very sensitive to moisture. Printing after absorbing moisture will result in ozzing, extruding with bubbles and rough surface appearance, thus reducing print quality. It is recommended that put the filament into a dry box (humidity below 15%) immediately after opening the QIDI PAHT-CF vacuum foil bag for printing. Please put the unused filament back into the original aluminum foil bag for sealed storage.

• After the printing, the printed part can be annealed to further improve the strength of QIDI PAHT-CF print part. Annealing conditions: place the printed part at 80-100°C for 4-6 hours and cool to room temperature naturally.

For more details please refer to: Filament Guide on WIKI.

Vacuum Aluminum Foil Packaging

According to the test, the water vapor transmission rate of ordinary sealed packaging is 4.76%, while the water vapor transmission rate of vacuum aluminum foil packaging we use is only 0.014%. It can be seen that vacuum aluminum foil packaging is more water-resistant.

Product Size

QIDI TECH UltraPA filament 1.75mmWorks perfectly with most FDM 3Dprinters on the market.

QIDI Plus4 3D Printer

QIDI Plus4 3D Printer

Qidi Tech Q1 Pro 3D Printer

Qidi Tech Q1 Pro 3D Printer

Qidi Tech X-Max 3 3D Printer

Qidi Tech X-Max 3 3D Printer

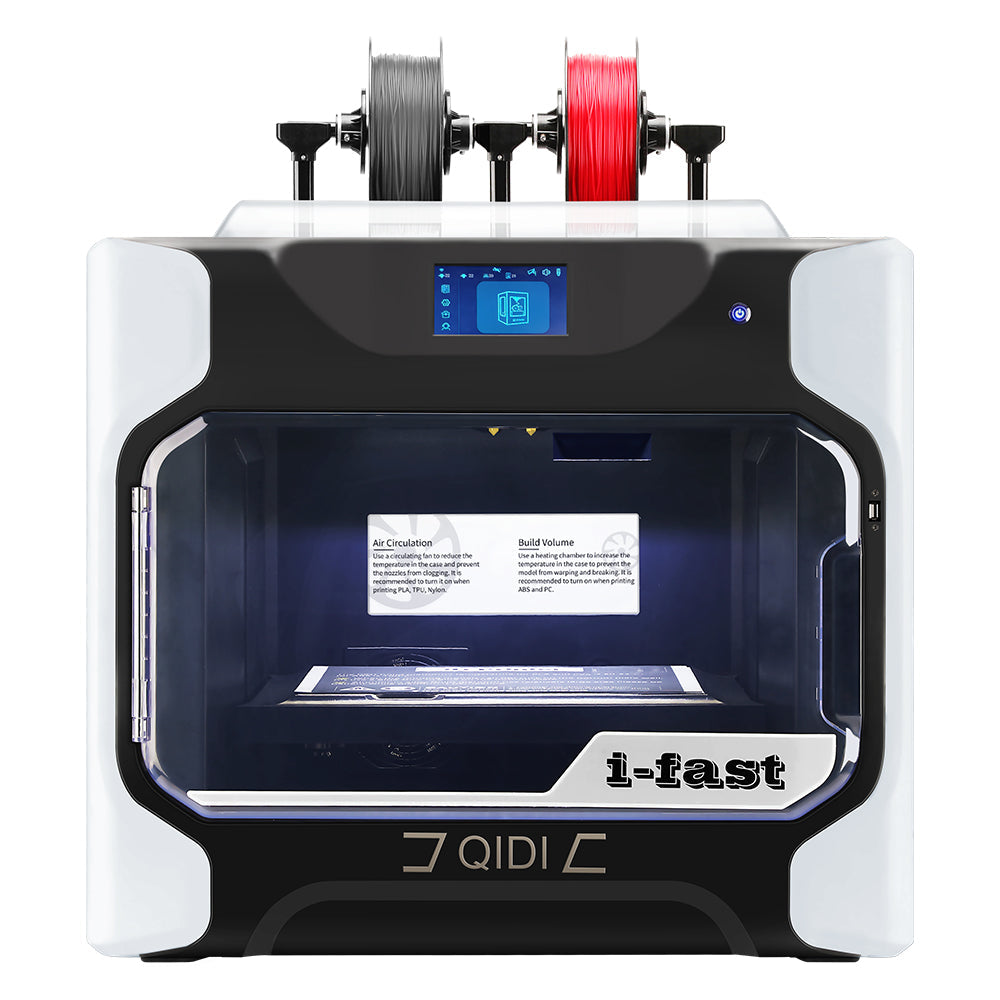

Qidi Tech I-Fast 3D Printer

Qidi Tech I-Fast 3D Printer

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/new_dcc96aa7-8efe-478b-ac13-cb35255e480d.jpg?v=1744696175&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/new_dcc96aa7-8efe-478b-ac13-cb35255e480d.jpg?v=1744696175&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1744695830&width=1000)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/3034a1133efe01daba919094b70c6310.jpg?v=1744695801&width=1000)