New Chapter of QIDISlicer

Background

As a middleman between 3D models and 3D printers, slicing software plays a crucial role in the 3D printing process. In the field of 3d printing, popular slicing software options include Cura, Prusa-Slicer, Simplify3D, and ideaMaker. At the heart of UltiMaker Cura is its powerful, open-source slicing engine, built through years of expert in-house development and user contributions.

QIDI Print slicer has always built on Cura's functionality and user interface, extending and customising it to meet the needs of our 3D printers, specific users or specific domains. However, when we synced to the latest slicing engine of Cura 5.3.0, the users have experienced some bugs when using the slicing software, which greatly affected the 3D printer experience.

Some bugs

- Adaptive Layerheights are not always working correctly

- Sometimes the slicer engine crashes, so customers need to rotate the model or move it away from the center.

- Some models have been slicing slowly than other slicer engines.

- The seam hiding function sometimes does not work correctly and seams do not print well.

- Combing Not In Skin can result in unexpected stringing.

- Random gcode code error causes printer to stop printing.

During high speed printing, the influence of these defects is amplified, significantly affecting the overall print quality. The Slicing Software based on Cura is no longer able to meet the high-speed printing requirements of the third-generation model.

New Chapter of QIDISlicer

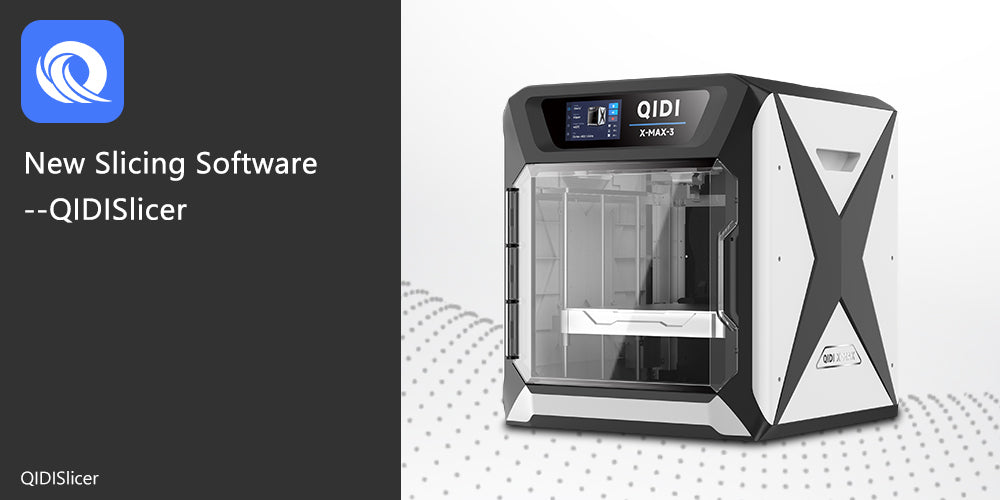

Since our new machine is ready, it is necessary that we must develop a reliable, streamlined, and precise slicing software that seamlessly integrates with QIDI high-speed 3D printer to offer customers optimal printing results. QIDI originated from the 3D printing community and is always listening to the voices of the community. PrusaSlice(by PrusaResearch), developed based on the open source slicing engine "Slic3r(by Alessandro Ranellucci with the help of many other contributors)", has gained popularity among printer enthusiasts due to its stable performance and diverse functions. Subsequently, Bambu Studio optimized the graphical interface based on PrusaSlicer to make it easier to use. Recently, Orcaslicer software has become popular among community enthusiasts. It is based on Bambu Studio and incorporates many features of SuperSlicer, including support for Klipper firmware. Based on PrusaSlicer and with reference to Bambu Studio and Orcaslicer, we spent over a month testing and editing code day and night to create QIDISlicer - an open source slicing software that perfectly fits our new model. We would like to extend our sincere gratitude to all the companies and individuals who have made invaluable contributions to the 3D community. As Josef Prusa said,Anyone developing something related to 3D printing today will benefit from more than ten years of continuous open-source development. The successful progress of our new slicing software owes to the open-source and sharing nature of the community. QIDISlicer is a new professional 3D printer slicing software,which is perfectly compatible with high-speed printers (Klipper firmware) and all 3D printing filaments of QIDI Technology. QIDISlicer supports multiple platforms and has a user-friendly interface and methods of use. It has comprehensive functions that enable easy 3D printing. QIDISlicer makes printing more stable, smoother surface, faster printing speed, faster slicing speed, and it is more suitable for high-speed printing for the speed division of different structural features.

New Features

- Add device remote console UI page in software

- New tree support uses significantly less filament

- Add pressure advance parameters setting

- Add printing tips

- Aligned Z Seam for better Z seam hiding

- Other features of PrusaSlicer 2.6.0

Future Plans

- Release QIDIslicer version adapted to Linux system.

- Auto calibrations for all printers (coming soon, thanks to @SoftFever and community for their contribution)

- Optimize UI and improve user experience.

- Optimized configuration files.

- Add new features (if you have any suggestions, you can send an email to karl@qd3dprinter.com. If the suggestion is adopted, you will get a mysterious gift.)

In the End

We would like to express our gratitude to the loyal Qidi 3D printer users for their unwavering support of our software. Their valuable opinions and feedback have been instrumental in identifying and correcting issues. At the same time, we extend our heartfelt appreciation to community enthusiasts for their contributions, continuous testing, feedback, development of plug-ins, writing of documents, sharing of experience, providing support, continuous improvement and promotion of the development of slice software, making it more powerful, stable and adaptable to user needs. The needs of our customers have always been our top priority.

Notice:

- QIDISlicer as a new software dedicated to QIDI's new high speed printers, please make sure your firmware version is V 4.0.0 or above.

- You can contact After-Sales Service to report issues and make suggestions.

Q2

Q2

Plus4

Plus4

QIDI Box

QIDI Box

Q1Pro

Q1Pro

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1763120465) Max3

Max3

I-Fast

I-Fast