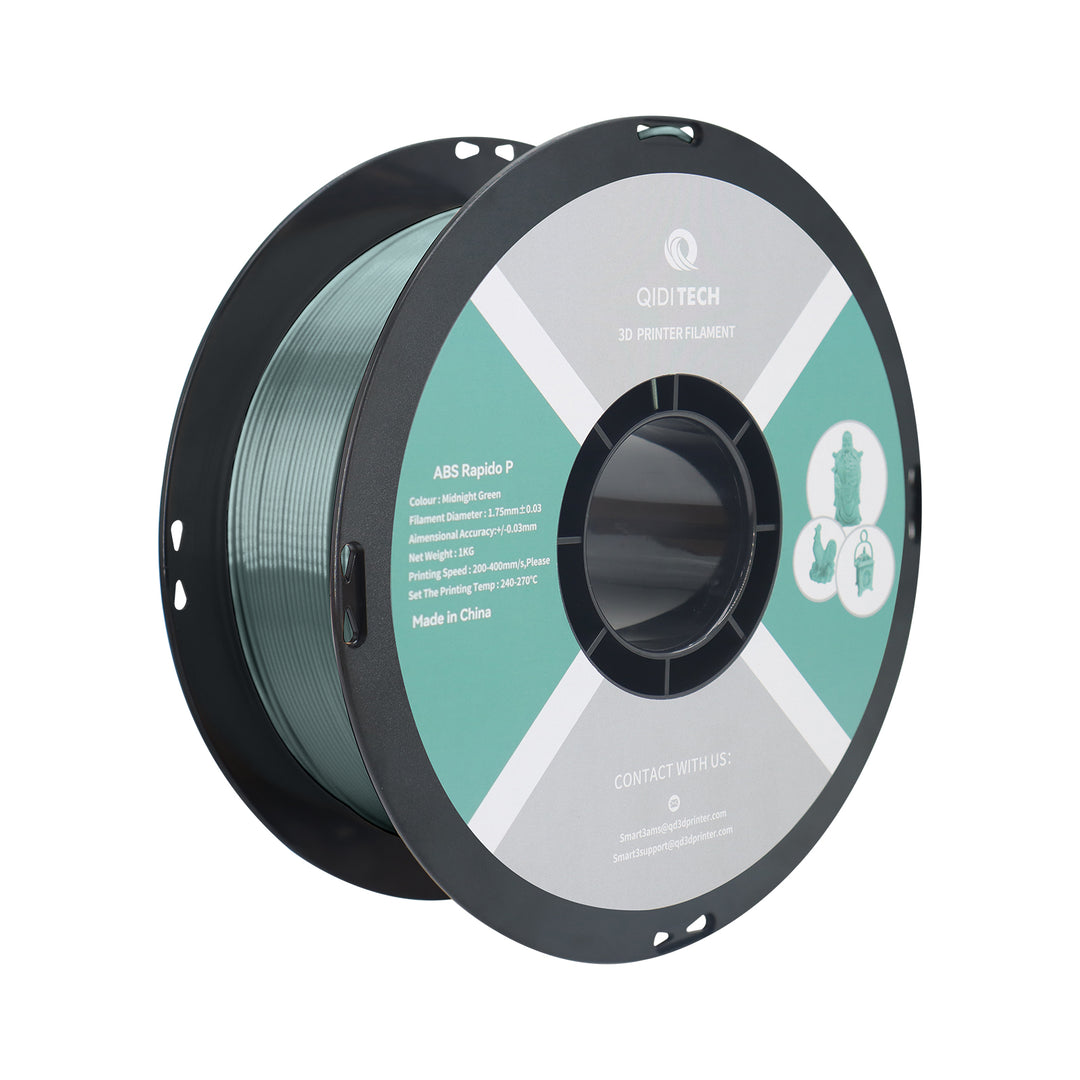

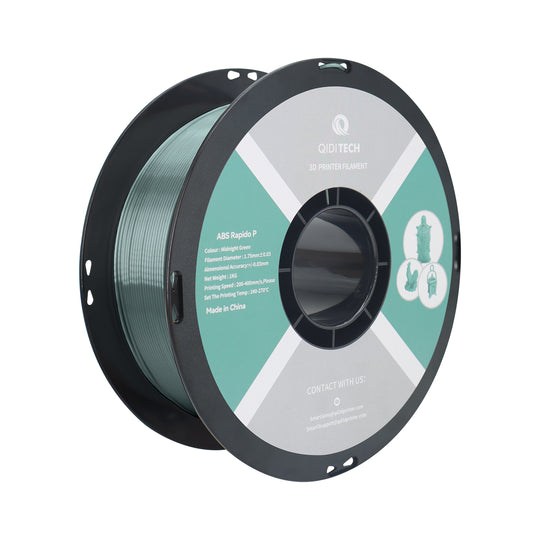

QIDI ABS Rapido Metal 3D-Druckerfilament

QIDI ABS Rapido Metallfilament-Modellanzeige

Produktgröße

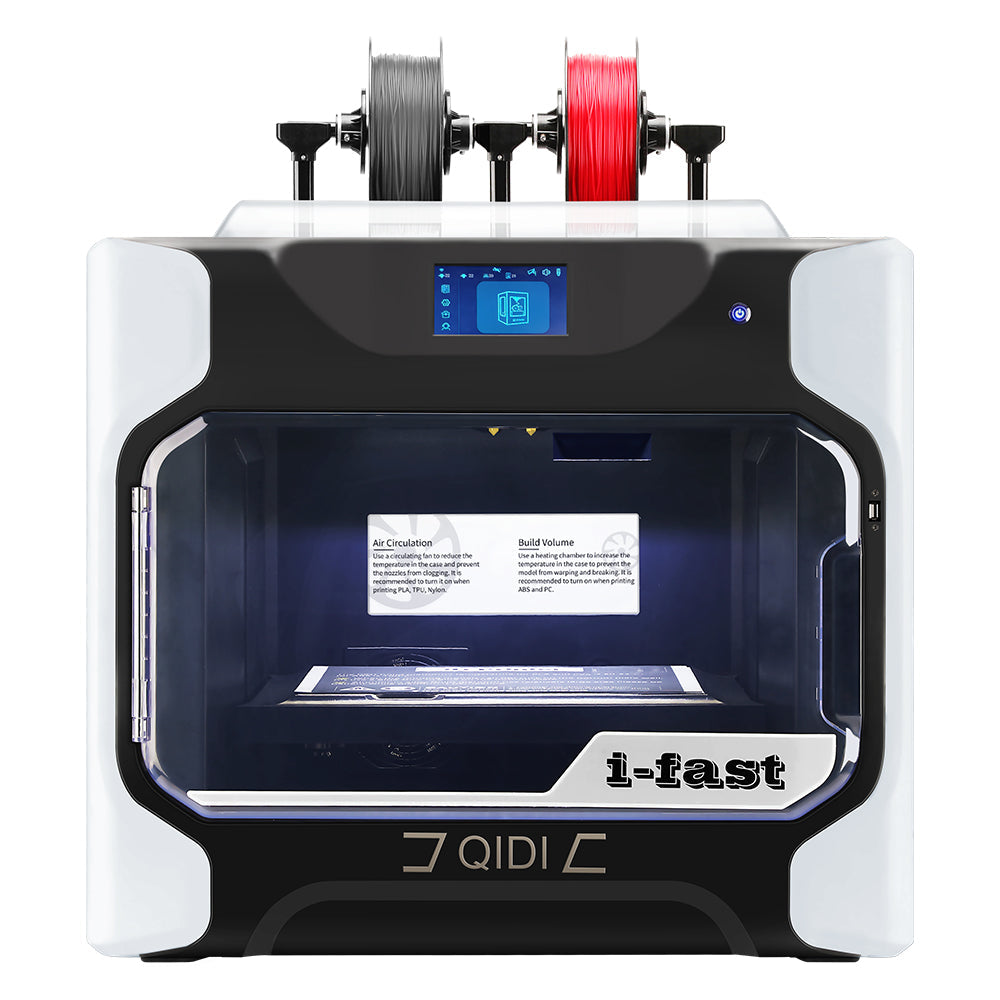

Zubehörkompatibilität

| Empfohlen | Nicht empfohlen | |

| Bauplatte | / | |

| Hotend | Messing-/Kupferbeschichtete Düse (0,2/0,4/0,6/0,8 mm) Bimetalldüse (0,4/0,6/0,8 mm) | Düse aus gehärtetem Stahl (0,4/0,6/0,8 mm) |

| Kleber | Klebestift/ 3D LAC Klebespray | / |

| Empfohlene Druckeinstellungen | |

| Trocknungseinstellungen (Schnelltrockner) | 60 °C,4-6 h |

| Drucken und Aufrechterhalten der Feuchtigkeit im Behälter | < 15 % relative Luftfeuchtigkeit (versiegelt, mit Trockenmittel) |

| Düsentemperatur | 220-250 °C |

| Betttemperatur (mit Kleber) | 80~100 °C |

| Druckgeschwindigkeit | 40-200 mm/s |

| Physikalische Eigenschaften | |

| Dichte | 1,05~1,07 g/cm³ |

| Vicat-Erweichungstemperatur | 91 °C |

| Wärmeformbeständigkeitstemperatur | 75 °C |

| Schmelztemperatur | 190 °C |

| Schmelzflussrate | 30~40 g/10 min |

| Mechanische Eigenschaften | |

| Zugfestigkeit | 34~37 MPa |

| Bruchdehnungsrate | 2 % bis 4 % |

| Emodul | 3400~4000 MPa |

| Schlagfestigkeit | 22~28 kJ/m² |

Drucktipps

1.

2.Schnelles Abkühlen kann zu Rissen oder ungleichmäßigem Glanz auf der Oberfläche führen

Weitere Einzelheiten finden Sie unter: Filament-Anleitung auf WIKI.

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1763120465)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1763120465&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/MAX3-buildvolume.jpg?v=1763120465&width=1000)