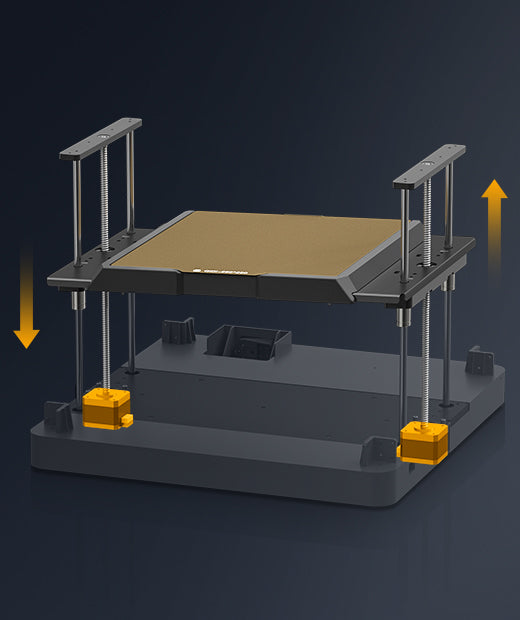

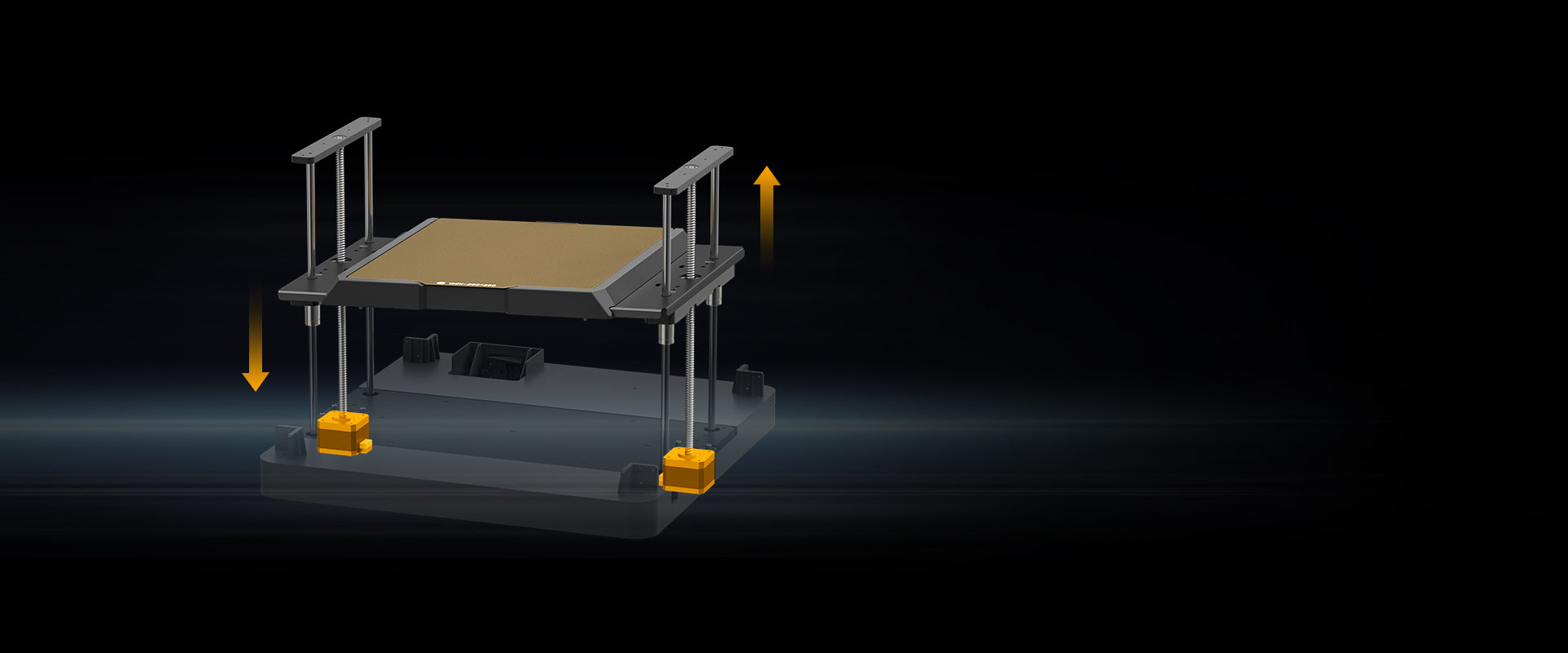

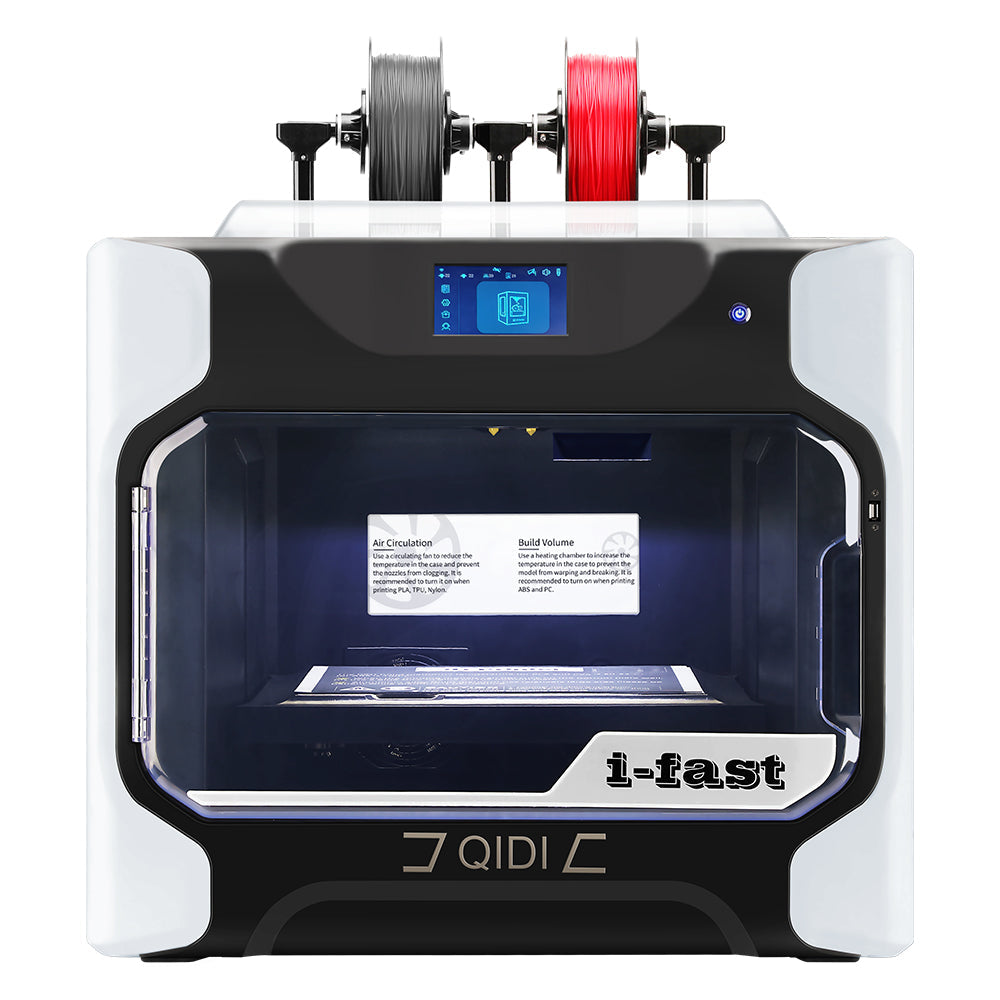

Independent dual Z motors

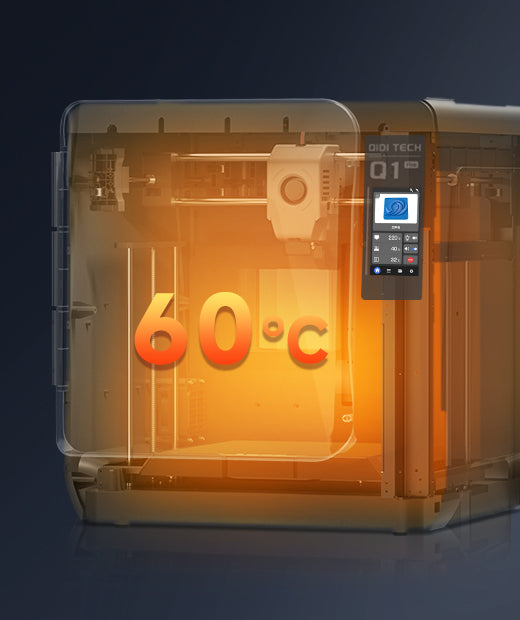

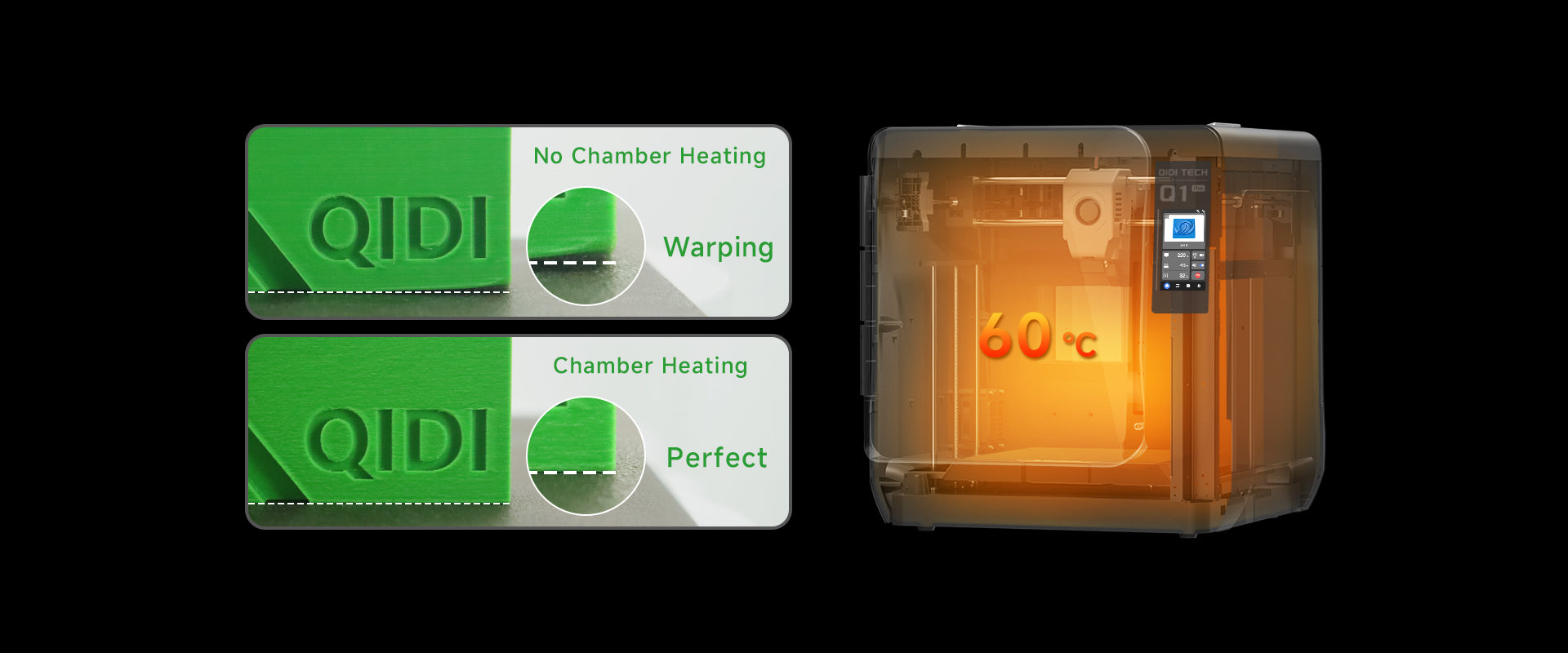

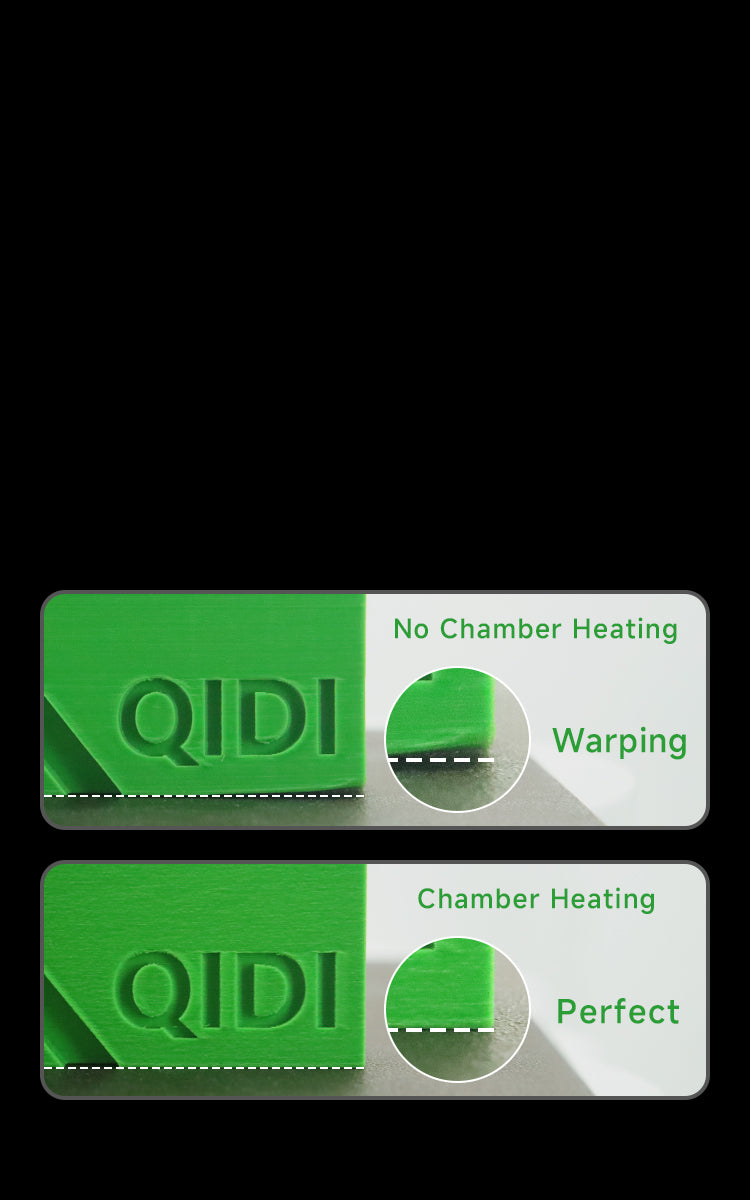

Active chamber heating

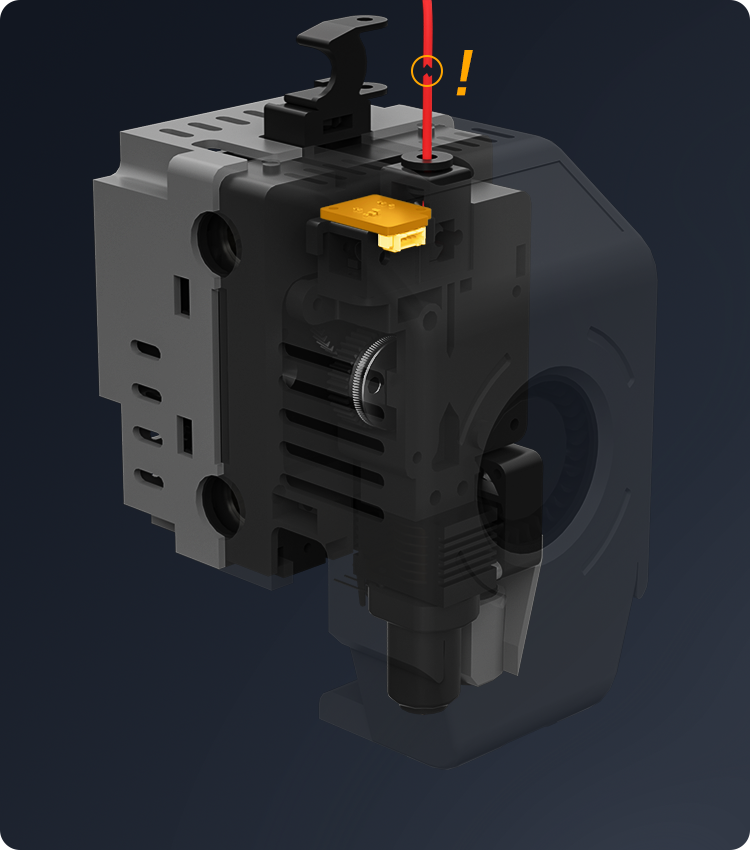

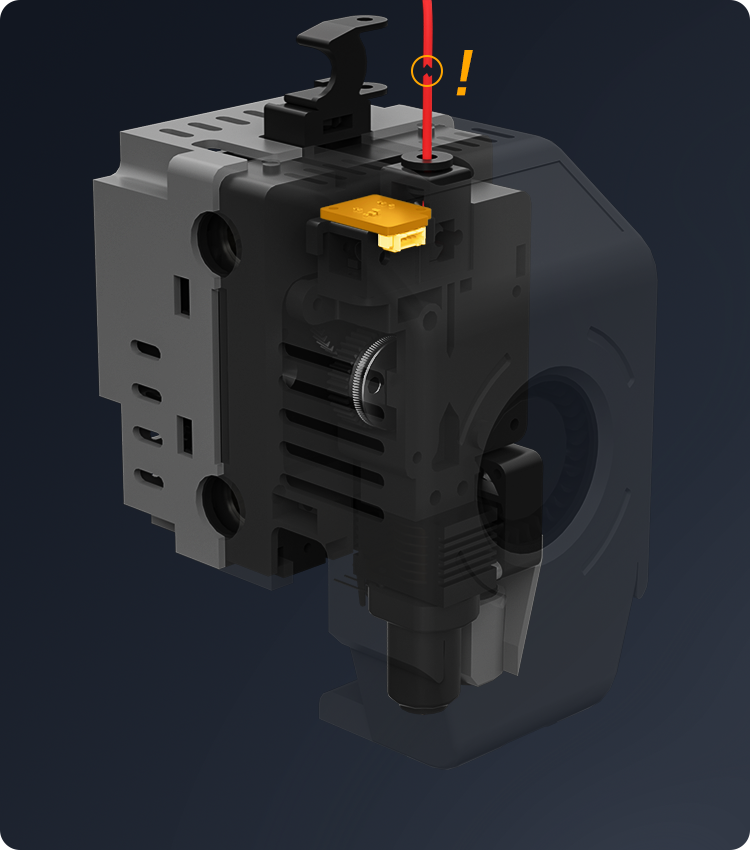

New Tri-metal hot end

Know more about

Temperature control

Active chamber heat as standard feature

Reduce warping, lmprove layer bonding, Better print quality

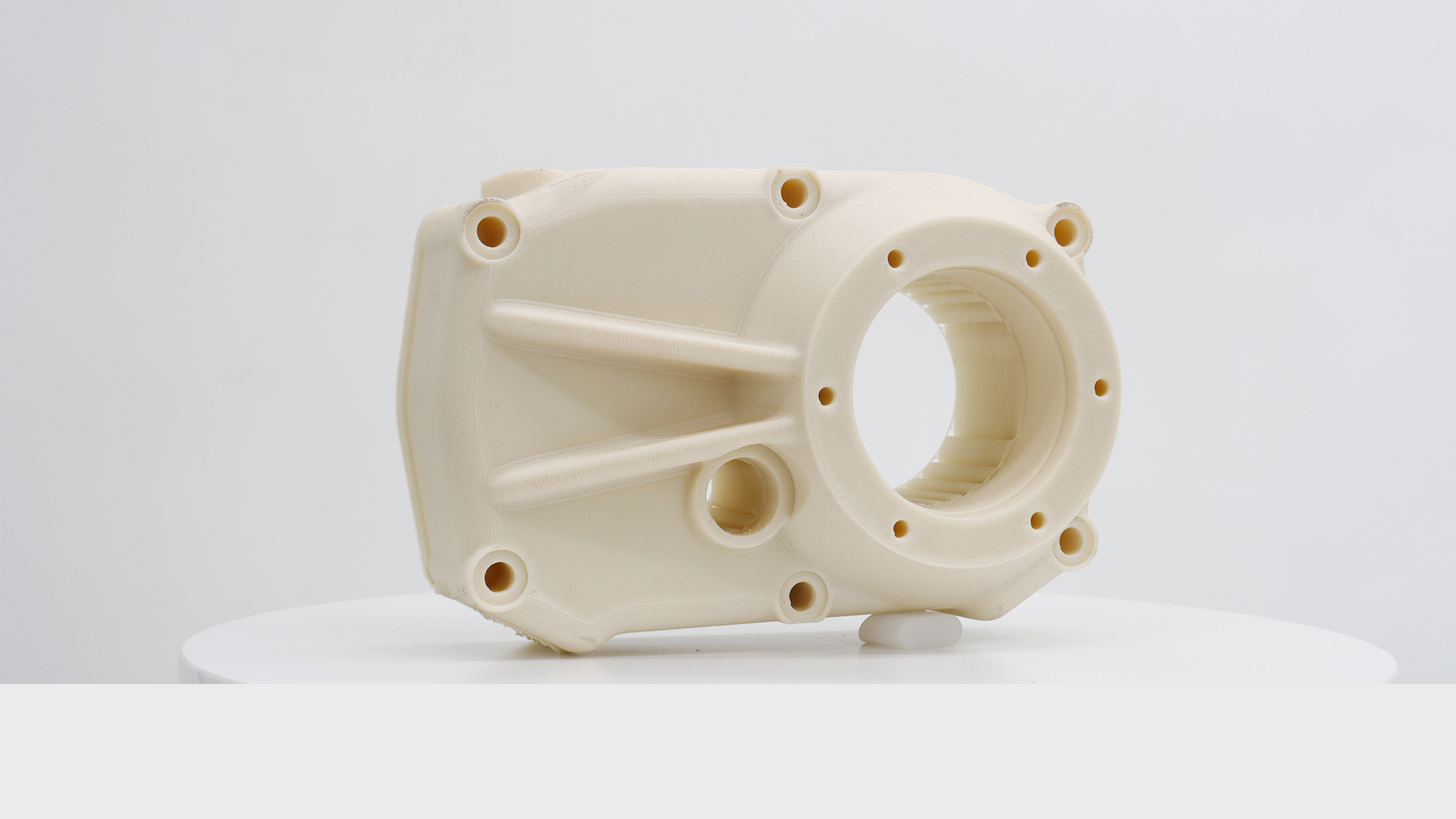

Especially for warp-prone

filaments such as ABS, PA, PC, etc

Maximum 350°C nozzle temp

Unlock High-temp filament

PAHT-CF, PET-CF, PA12-CF, ABS-GF25, PC/ABS-FR etc

Gives models better mechanical properties

Material:PAHT-CF Temp:320℃ Bed:100℃

Chamber:55℃

Independent dual Z motors

Without belt

Automatic tilt leveling

Higher precision, more stable

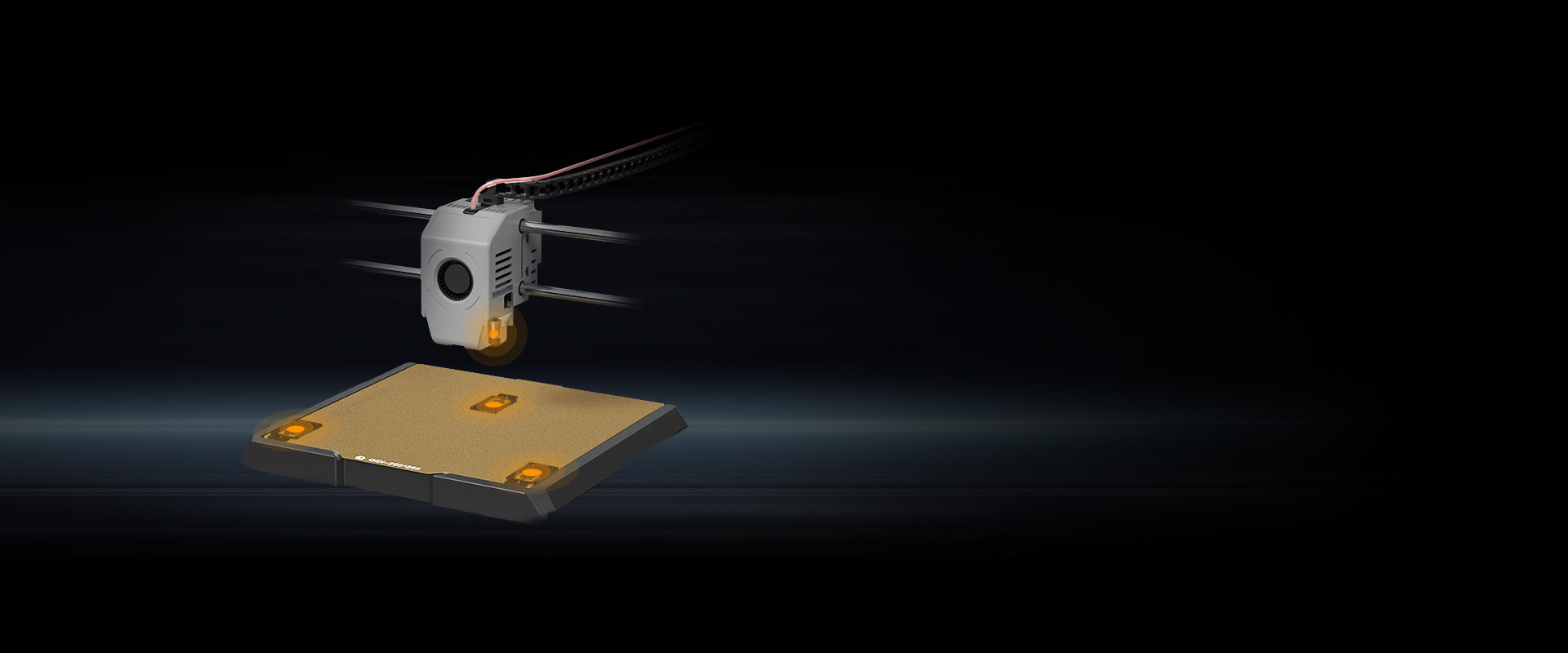

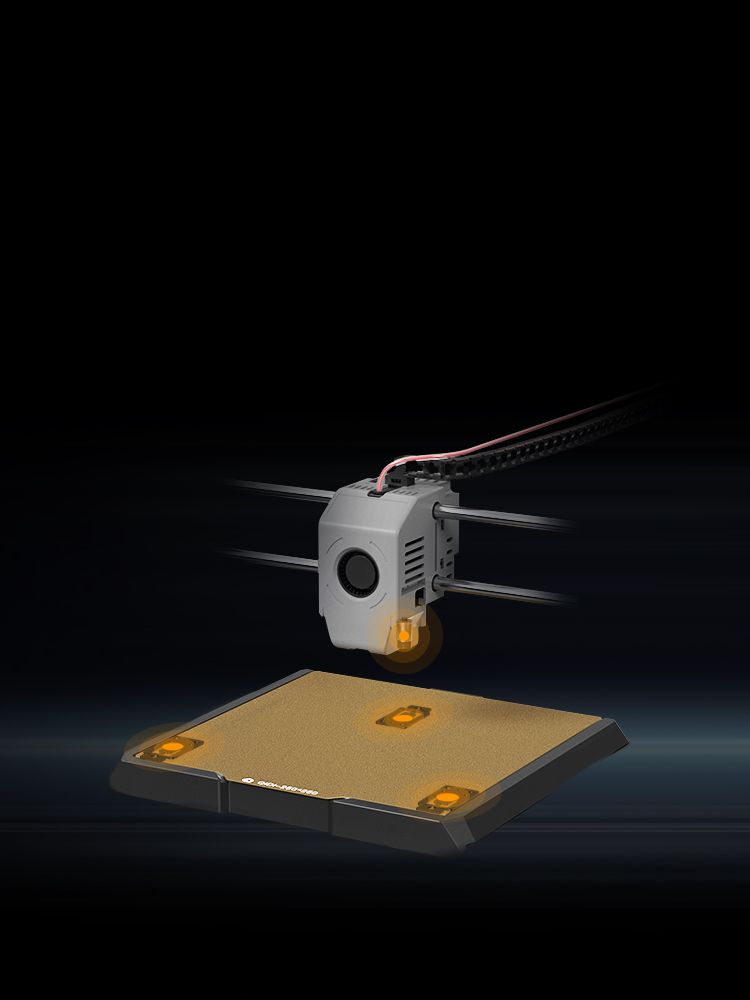

Dual Sensor Auto Bed Leveling

Doubly guaranteed

Perfect first layer for every time

Auto measure Z-offset

Add a nozzle cleaner

No more leveling paper as reference

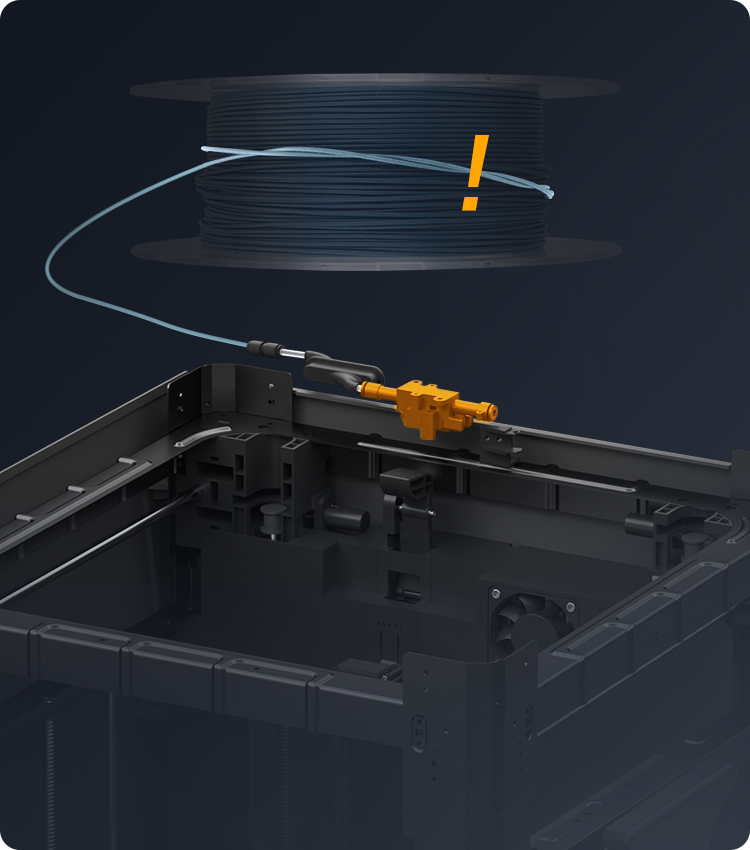

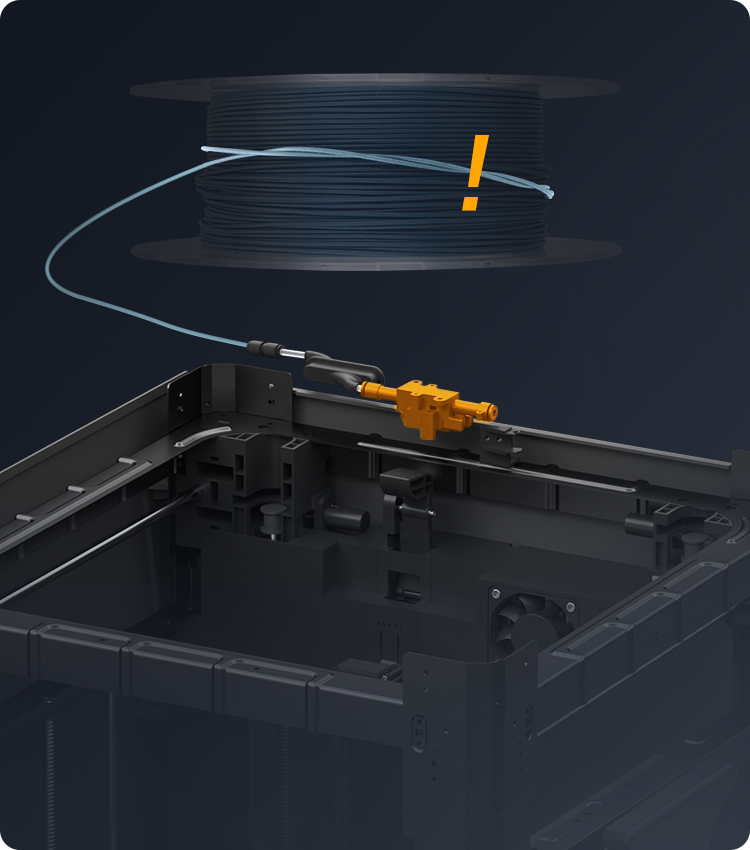

Comprehensive filament detection system

1. Filament Runout Detection

2. Filament Tangle Detection

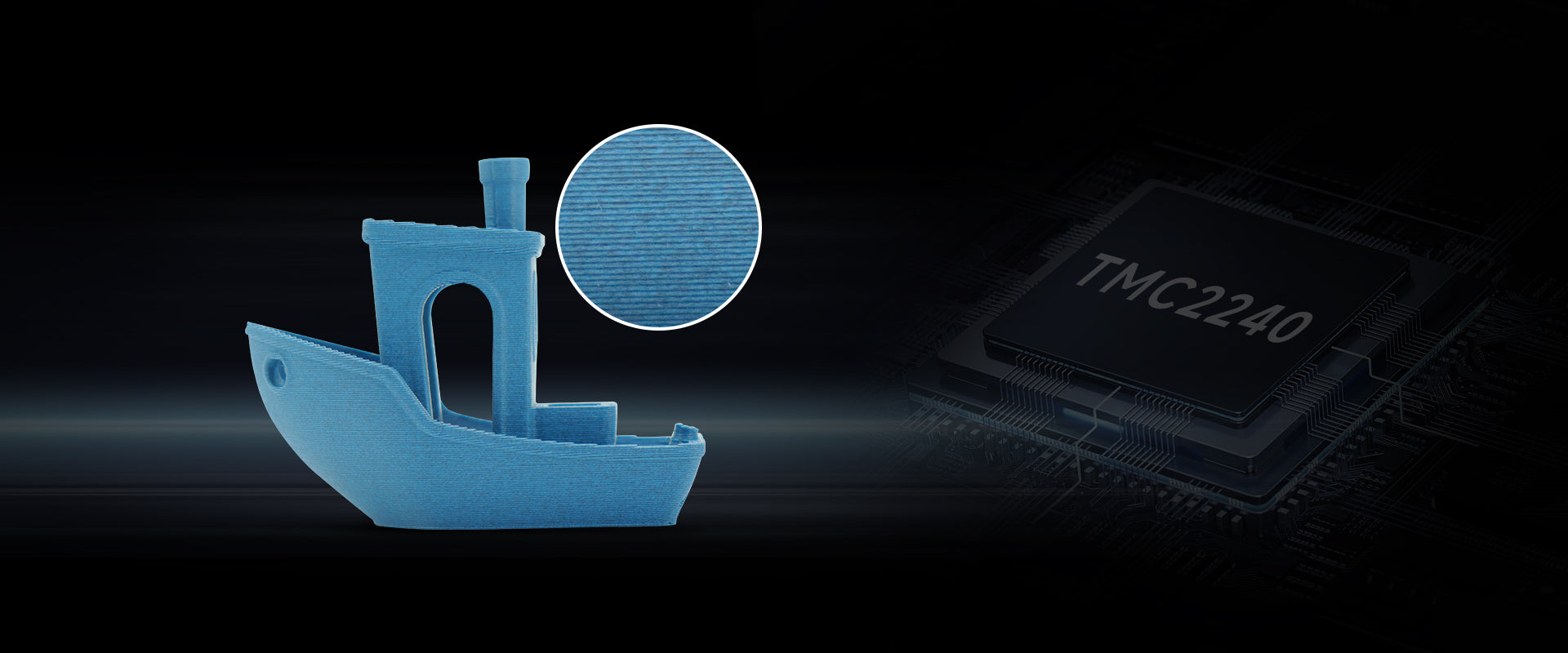

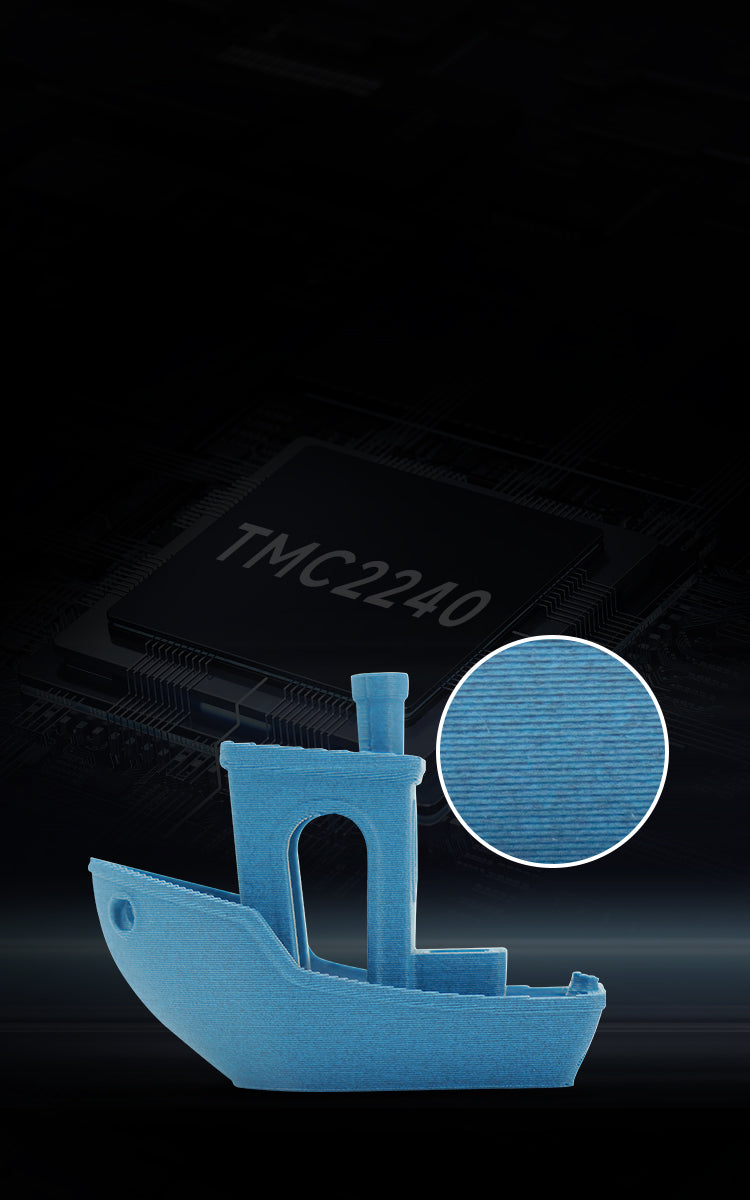

High speed, precise and stable

TMC2240

driver

Reducing power consumption and heat generation

Utilizes SpreadCycle technology

for

reduced vibration

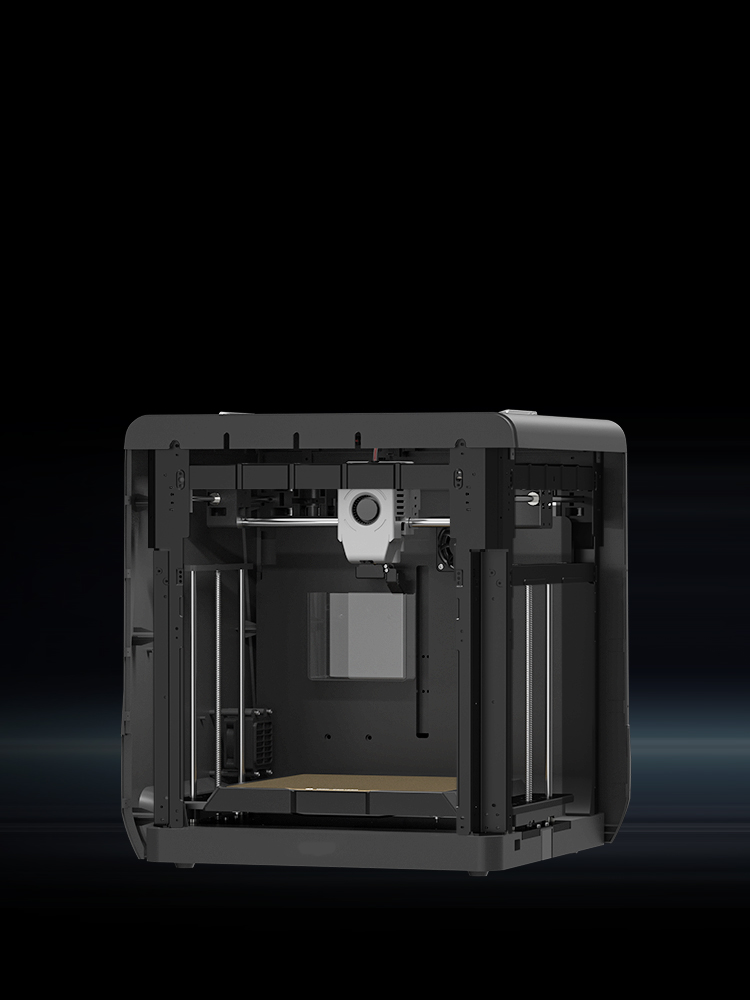

Lightweight CoreXY for ultra-fast acceleration

Reliable as always, solid materials

Fully metal frame structure

Metal bottom reinforcement for stability

Klipper 64-bit Processors

32G-EMMC Large

memory

capacity

150M Wi-Fi 6 High-speed transport

Open source and easy to expand

1080P Camera

Timelapse Supported,share your prints

Easy remote monitoring

QIDI Mobile Application

Remote 3D printer at any time

Skip failed 3D printing objects

Reduce filament

waste

10 mins

Right

out of

the box

Precision made easy by auto calibration

Start in one click

QIDI Tech has been manufacturing 3D printing machine since 2014

We are committed to developing a full range of high-quality FDM printers for practical

applications in multiple industries

so that products can create value for customers in 3D

printing.

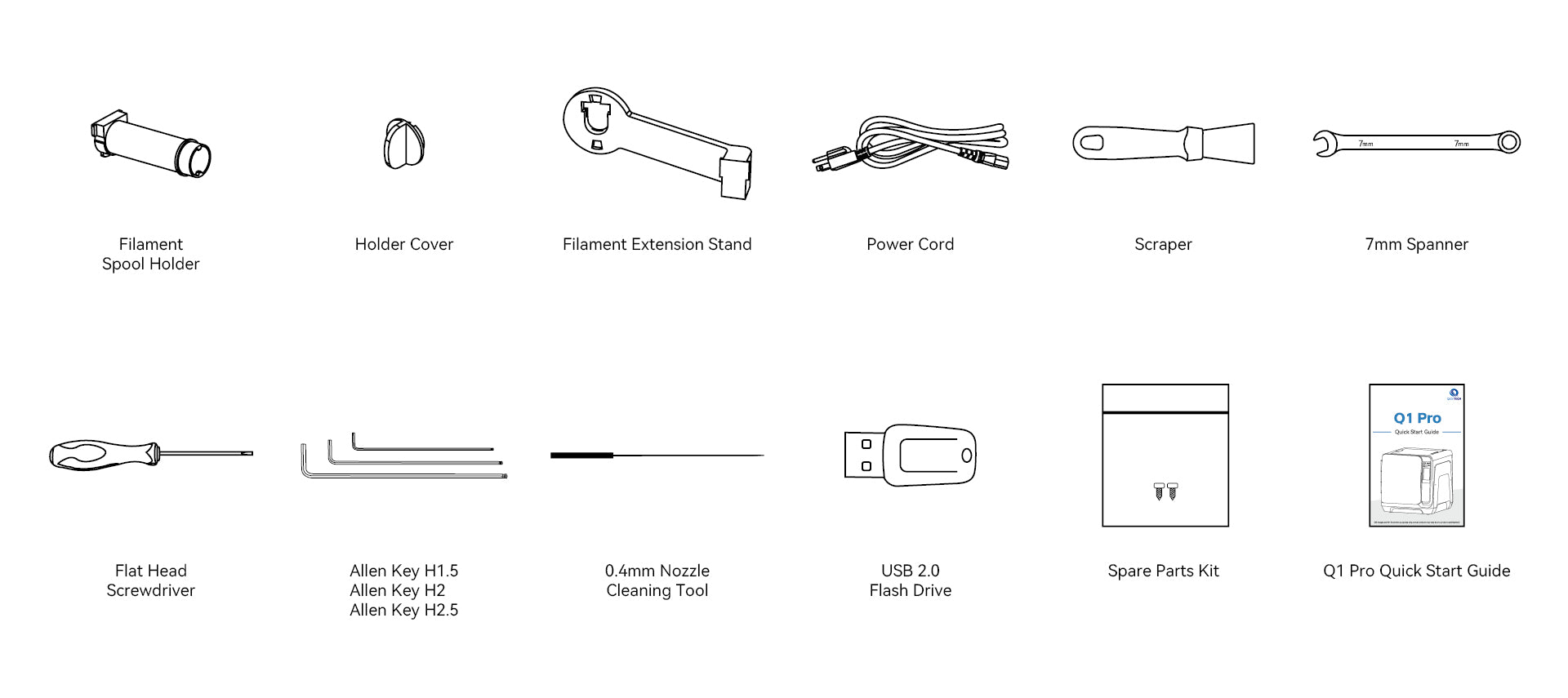

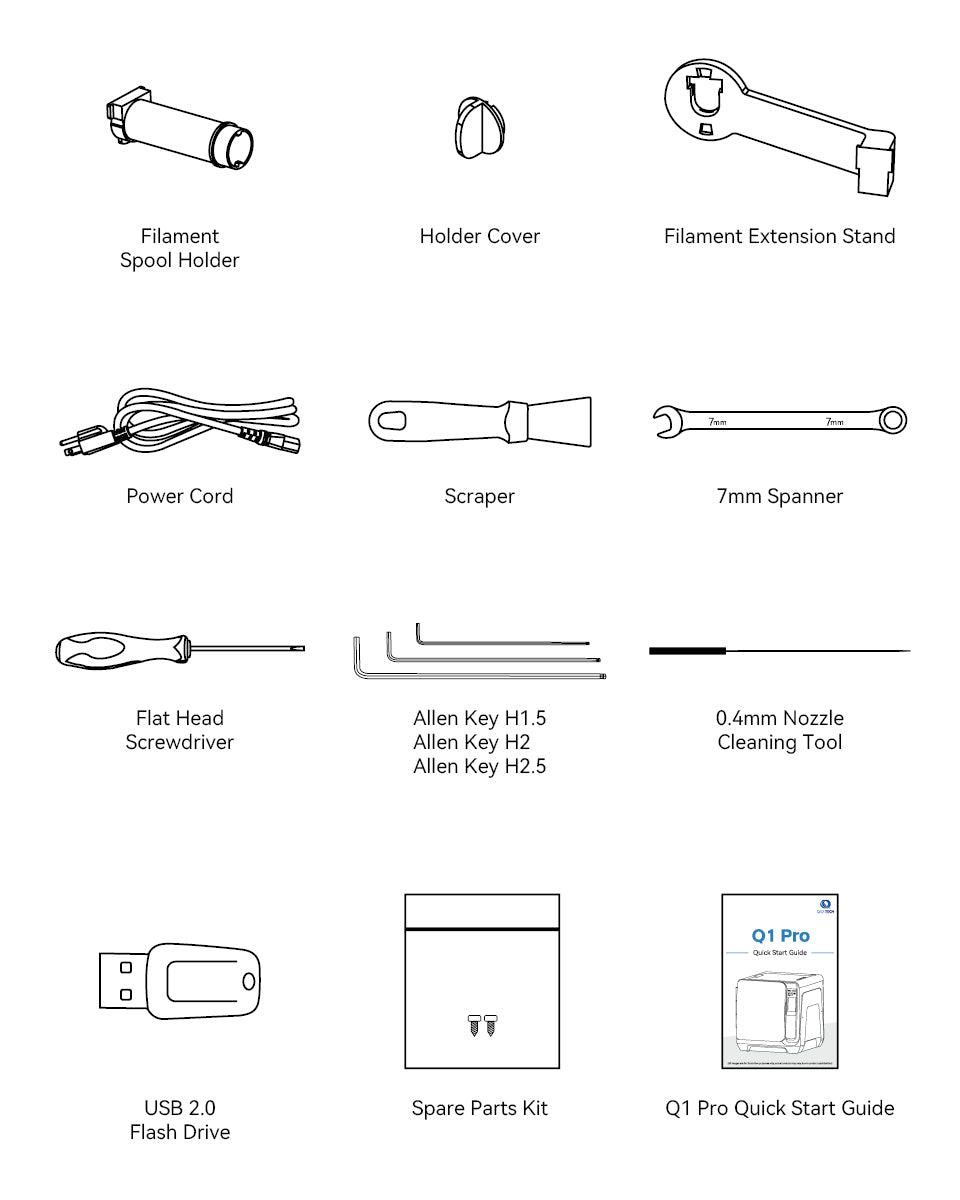

What's in the box

QI Pro Specifications

| Item | Specification | Item | Specification |

| Print Size (W*D*H): | 245*245*240 mm | Auxiliary Part Cooling Fan: | ✔ |

| Printer Dimensions: | 477*467*489 mm | Chamber Circulation Fan: | ✔ |

| Package Dimensions: | 545*535*595mm | Chamber Temperature: | 60° C Independent Chamber Heating |

| Cross Weight: | 20.3kg | Recommended Filament: | PLA, ABS, ASA, PETG |

| Net Wetiht: | 17kg | Compatible Filament: | TPU,PA, PC, Carbon/ Glass Fiber Reinforced Polymer |

| XY Structure: | CoreXY | Dry box: | Optional |

| X/Y Axis: | 10mm/8mm High hardness linear hollow steel shafts belt tensioned automatically |

Filament Tangle Detection: | ✔ |

| Z Axis: | Dual Independent Lead Screw Motors | Filament Run Out Sensor: | ✔ |

| Print Head Temperature: | ≤ 350℃ | Automatic Leveling: | Hands-free Automatic Leveling |

| Extruder: | Direct Extruder Hardened Steel Gears |

Input Shaping: | ✔ |

| Hot End: | Ceramic Plate Heating Hot End | Power Loss Recovery: | ✔ |

| Nozzle: | Bimetal Nozzle | Voltage: | 100-240 VAC, 50/60Hz |

| Nozzle Diameter: | 0.4mm (0.2/0.6/0.8mm Optional) |

Rated Power: | 350W+300W(Chamber Heater) |

| Filament Diameter: | 1.75mm | Display Screen: | 4.3 Inch 272*480 Touch Screen |

| Printing Platform: | Aluminum Substrate Heating Bed | Storage: | 32G EMMC and USB2.0 Flash Drive |

| Printing Plate: | Dual-Sided Textured PEI Plate | Camera: | Low Framerate Camera (Up to 1080P) Timelapse Supported |

| Hot Bed Temperature: | ≤ 120℃ | Wifi Module: | 150M 2.4G |

| Max Speed of Tool Head: | 600mm/s | Slicer: | QIDI Slicer and other third-party software, such as PrusaSlicer, Orca etc. |

| Acceleration: | ≤20000mm/s^2 | File Formats for Slicing: | STL, OBJ, 3MF,STEP,STP |

| Operating System: | Windows、MacOS、Linux | Q1 Pro TDS: Download | |

| Item | Specification |

| Print Size (W*D*H): | 245*245*240 mm |

| Auxiliary Part Cooling Fan: | ✔ |

| Printer Dimensions: | 477*467*489 mm |

| Chamber Circulation Fan: | ✔ |

| Package Dimensions: | 545*535*595mm |

| Chamber Temperature: | 60° C Independent Chamber Heating |

| Cross Weight: | 20.3kg |

| Recommended Filament: | PLA, ABS, ASA, PETG |

| Compatible Filament: | TPU,PA, PC, Carbon/ Glass Fiber Reinforced Polymer |

| XY Structure: | CoreXY |

| Dry box: | Optional |

| X/Y Axis: | 10mm/8mm High hardness linear hollow steel shafts belt tensioned automatically |

| Filament Tangle Detection: | ✔ |

| Z Axis: | Dual Independent Lead Screw Motors |

| Filament Run Out Sensor: | ✔ |

| Print Head Temperature: | ≤ 350℃ |

| Automatic Leveling: | Hands-free Automatic Leveling |

| Extruder: | Direct Extruder Hardened Steel Gears |

| Input Shaping: | ✔ |

| Hot End: | Ceramic Plate Heating Hot End |

| Power Loss Recovery: | ✔ |

| Nozzle: | Bimetal Nozzle |

| Voltage: | 100-240 VAC, 50/60Hz |

| Nozzle Diameter: | 0.4mm (0.2/0.6/0.8mm Optional) |

| Rated Power: | 350W+300W(Chamber Heater) |

| Filament Diameter: | 1.75mm |

| Display Screen: | 4.3 Inch 272*480 Touch Screen |

| Printing Platform: | Aluminum Substrate Heating Bed |

| Storage: | 32G EMMC and USB2.0 Flash Drive |

| Printing Plate: | Dual-Sided Textured PEI Plate |

| Camera: | Low Framerate Camera (Up to 1080P) Timelapse Supported |

| Hot Bed Temperature: | ≤ 120℃ |

| Wifi Module: | 150M 2.4G |

| Max Speed of Tool Head: | 600mm/s |

| Slicer: | QIDI Slicer and other third-party software, such as PrusaSlicer, Orca etc. |

| Acceleration: | ≤20000mm/s^2 |

| File Formats for Slicing: | STL, OBJ, 3MF,STEP,STP |

| Operating System: | Windows、MacOS、Linux |

| Q1 Pro TDS: Download | |

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/products/X-MAX3-3D-Printer-02.png?v=1763120465)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/3034a1133efe01daba919094b70c6310.jpg?v=1766111253&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600_52859f3a-0252-4a11-80ed-685f74178d96.jpg?v=1766111253&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600-2.jpg?v=1766111253&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600-4.jpg?v=1766111253&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600-5.jpg?v=1766111253&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600-6.jpg?v=1766111253&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600-7.jpg?v=1766111253&width=1080)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/3034a1133efe01daba919094b70c6310.jpg?v=1766111253&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600_52859f3a-0252-4a11-80ed-685f74178d96.jpg?v=1766111253&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600-2.jpg?v=1766111253&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600-4.jpg?v=1766111253&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600-5.jpg?v=1766111253&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600-6.jpg?v=1766111253&width=540)

![[Qidi X-CF Pro, speziell für den Druck von Kohlefaser und Nylon entwickelt] - [QIDI Online Shop DE]](http://eu.qidi3d.com/cdn/shop/files/1600-7.jpg?v=1766111253&width=540)